Transform your PDFs into Flipbooks and boost your revenue!

Leverage SEO-optimized Flipbooks, powerful backlinks, and multimedia content to professionally showcase your products and significantly increase your reach.

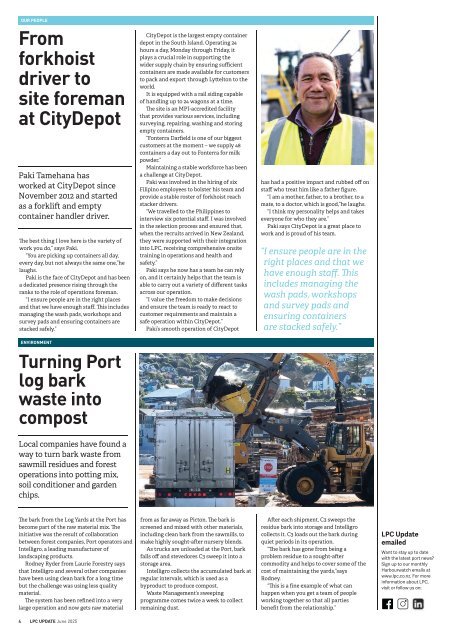

OUR PEOPLE<br />

From<br />

forkhoist<br />

driver to<br />

site foreman<br />

at CityDepot<br />

Paki Tamehana has<br />

worked at CityDepot since<br />

November 2012 and started<br />

as a forklift and empty<br />

container handler driver.<br />

The best thing I love here is the variety of<br />

work you do,” says Paki.<br />

“You are picking up containers all day,<br />

every day, but not always the same one,”he<br />

laughs.<br />

Paki is the face of CityDepot and has been<br />

a dedicated presence rising through the<br />

ranks to the role of operations foreman.<br />

“I ensure people are in the right places<br />

and that we have enough staff. This includes<br />

managing the wash pads, workshops and<br />

survey pads and ensuring containers are<br />

stacked safely.”<br />

CityDepot is the largest empty container<br />

depot in the South Island. Operating 24<br />

hours a day, Monday through Friday, it<br />

plays a crucial role in supporting the<br />

wider supply chain by ensuring sufficient<br />

containers are made available for customers<br />

to pack and export through Lyttelton to the<br />

world.<br />

It is equipped with a rail siding capable<br />

of handling up to 24 wagons at a time.<br />

The site is an MPI-accredited facility<br />

that provides various services, including<br />

surveying, repairing, washing and storing<br />

empty containers.<br />

“Fonterra Darfield is one of our biggest<br />

customers at the moment – we supply 48<br />

containers a day out to Fonterra for milk<br />

powder.”<br />

Maintaining a stable workforce has been<br />

a challenge at CityDepot.<br />

Paki was involved in the hiring of six<br />

Filipino employees to bolster his team and<br />

provide a stable roster of forkhoist reach<br />

stacker drivers.<br />

“We travelled to the Philippines to<br />

interview six potential staff. I was involved<br />

in the selection process and ensured that,<br />

when the recruits arrived in New Zealand,<br />

they were supported with their integration<br />

into LPC, receiving comprehensive onsite<br />

training in operations and health and<br />

safety.”<br />

Paki says he now has a team he can rely<br />

on, and it certainly helps that the team is<br />

able to carry out a variety of different tasks<br />

across our operation.<br />

“I value the freedom to make decisions<br />

and ensure the team is ready to react to<br />

customer requirements and maintain a<br />

safe operation within CityDepot.”<br />

Paki’s smooth operation of CityDepot<br />

has had a positive impact and rubbed off on<br />

staff who treat him like a father figure.<br />

“I am a mother, father, to a brother, to a<br />

mate, to a doctor, which is good,”he laughs.<br />

“I think my personality helps and takes<br />

everyone for who they are.”<br />

Paki says CityDepot is a great place to<br />

work and is proud of his team.<br />

“I ensure people are in the<br />

right places and that we<br />

have enough staff. This<br />

includes managing the<br />

wash pads, workshops<br />

and survey pads and<br />

ensuring containers<br />

are stacked safely.”<br />

ENVIRONMENT<br />

Turning Port<br />

log bark<br />

waste into<br />

compost<br />

Local companies have found a<br />

way to turn bark waste from<br />

sawmill residues and forest<br />

operations into potting mix,<br />

soil conditioner and garden<br />

chips.<br />

The bark from the Log Yards at the Port has<br />

become part of the raw material mix. The<br />

initiative was the result of collaboration<br />

between forest companies, Port operators and<br />

Intelligro, a leading manufacturer of<br />

landscaping products.<br />

Rodney Ryder from Laurie Forestry says<br />

that Intelligro and several other companies<br />

have been using clean bark for a long time<br />

but the challenge was using less quality<br />

material.<br />

The system has been refined into a very<br />

large operation and now gets raw material<br />

from as far away as Picton. The bark is<br />

screened and mixed with other materials,<br />

including clean bark from the sawmills, to<br />

make highly sought-after nursery blends.<br />

As trucks are unloaded at the Port, bark<br />

falls off and stevedores C3 sweep it into a<br />

storage area.<br />

Intelligro collects the accumulated bark at<br />

regular intervals, which is used as a<br />

byproduct to produce compost.<br />

Waste Management’s sweeping<br />

programme comes twice a week to collect<br />

remaining dust.<br />

After each shipment, C3 sweeps the<br />

residue bark into storage and Intelligro<br />

collects it. C3 loads out the bark during<br />

quiet periods in its operation.<br />

“The bark has gone from being a<br />

problem residue to a sought-after<br />

commodity and helps to cover some of the<br />

cost of maintaining the yards,”says<br />

Rodney.<br />

“This is a fine example of what can<br />

happen when you get a team of people<br />

working together so that all parties<br />

benefit from the relationship.”<br />

LPC Update<br />

emailed<br />

Want to stay up to date<br />

with the latest port news?<br />

Sign up to our monthly<br />

<strong>Harbour</strong>watch emails at<br />

www.lpc.co.nz. For more<br />

information about LPC,<br />

visit or follow us on:<br />

4 LPC UPDATE <strong>June</strong> <strong>2025</strong>