Cone Drive Accudrive Producst

- 1. Cone Drive AccuDrive Products

- 2. Cone Drive Locations 200,000 ft 2 manufacturing space 210 employees total Focused in Double Enveloping worm gear technologies Offer widest portfolio of gear products in North America Ludington, MI Traverse City, MI

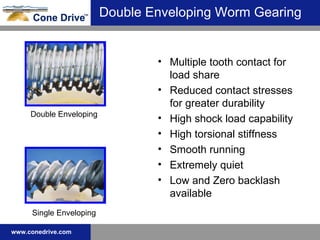

- 3. Double Enveloping Worm Gearing Multiple tooth contact for load share Reduced contact stresses for greater durability High shock load capability High torsional stiffness Smooth running Extremely quiet Low and Zero backlash available Double Enveloping Single Enveloping

- 5. AccuDrive Series W - Whisperdrive Meeting the precision needs of the Motion Control market

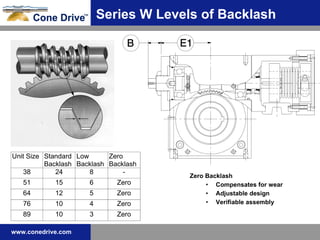

- 6. Series W - Whisperdrive Five Sizes 38, 51, 64, 76, 89 Exact Ratios Three Levels of Backlash Standard , Low, Zero Metric / Inch shafts Output Options Shrink Disc or Direct Mount Solid or Hollow Specials Ratios, Shafts, Plating Double enveloping worm gearing – 300% Overload 5 Year Warranty

- 7. Zero Backlash Compensates for wear Adjustable design Verifiable assembly Series W Levels of Backlash

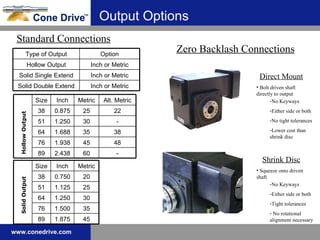

- 8. Output Options Zero Backlash Connections Direct Mount Bolt driven shaft directly to output No Keyways Either side or both No tight tolerances Lower cost than shrink disc Shrink Disc Squeeze onto driven shaft No Keyways Either side or both Tight tolerances No rotational alignment necessary Standard Connections Solid Output Hollow Output Inch or Metric Solid Double Extend Inch or Metric Solid Single Extend Inch or Metric Hollow Output Option Type of Output 2.438 1.938 1.688 1.250 0.875 Inch 60 45 35 30 25 Metric - 48 38 - 22 Alt. Metric 64 76 89 51 38 Size 1.875 1.500 1.250 1.125 0.750 Inch 45 35 30 25 20 Metric 64 76 89 51 38 Size

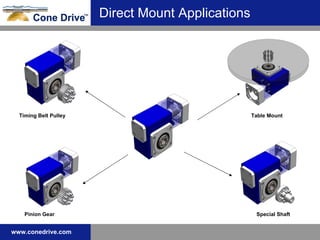

- 9. Versatility of Applications… Direct Mount Applications Timing Belt Pulley Table Mount Pinion Gear Special Shaft

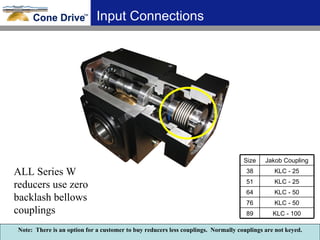

- 10. Input Connections ALL Series W reducers use zero backlash bellows couplings Note: There is an option for a customer to buy reducers less couplings. Normally couplings are not keyed. KLC - 100 89 KLC - 50 76 KLC - 50 64 KLC - 25 51 KLC - 25 38 Jakob Coupling Size

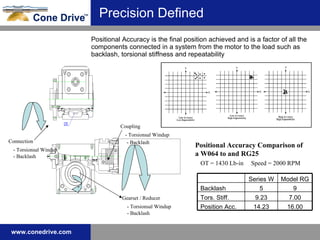

- 11. Positional Accuracy is the final position achieved and is a factor of all the components connected in a system from the motor to the load such as backlash, torsional stiffness and repeatability Coupling - Torsionsal Windup - Backlash Gearset / Reducer - Torsionsal Windup - Backlash Connection - Torsionsal Windup - Backlash OT = 1430 Lb-in Speed = 2000 RPM Positional Accuracy Comparison of a W064 to and RG25 Precision Defined 16.00 14.23 Position Acc. 7.00 9.23 Tors. Stiff. 9 5 Backlash Model RG Series W

- 12. - Maximim Cyclic Speeds of 6,000 RPM continuous of 4,000 RPM - Reduces backlash (no looseness setting based on speed). - Helps to reduce friction and heat (compared to taper rollers). - Housings / Caps / Carriers aluminum - All components black anodized. - Option for white epoxy or “steel it” paint. - Double seals on both the input and output shaft. - O-Rings on both the input and output shaft. - No vents. - IP65 Rated. Features & Benefits Speed Ball Bearings Weight Environmental Protection

- 13. AccuDrive Model RG Moderate precision for the Motion Control market

- 14. Output Connections Output Options Flange Mount -Either side or both Shrink Disc Squeeze onto driven shaft No Keyways Either side or both Tight tolerances No rotational alignment necessary Standard Connections Solid Output Hollow Output Inch or Metric Solid Double Extend Inch or Metric Solid Single Extend Inch or Metric Hollow Output Option Type of Output 2.438 1.938 1.688 1.250 0.875 Inch 60 45 35 30 25 Metric 25 30 35 20 15 Size 1.875 1.500 1.250 1.125 0.750 Inch 45 35 30 25 20 Metric 25 30 35 20 15 Size

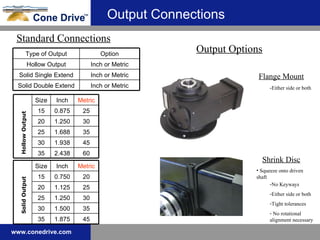

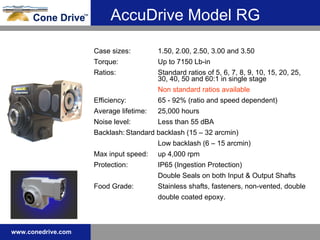

- 15. Case sizes: 1.50, 2.00, 2.50, 3.00 and 3.50 Torque: Up to 7150 Lb-in Ratios: Standard ratios of 5, 6, 7, 8, 9, 10, 15, 20, 25, 30, 40, 50 and 60:1 in single stage Non standard ratios available Efficiency: 65 - 92% (ratio and speed dependent) Average lifetime: 25,000 hours Noise level: Less than 55 dBA Backlash: Standard backlash (15 – 32 arcmin) Low backlash (6 – 15 arcmin) Max input speed: up 4,000 rpm Protection: IP65 (Ingestion Protection) Double Seals on both Input & Output Shafts Food Grade: Stainless shafts, fasteners, non-vented, double double coated epoxy. AccuDrive Model RG

- 16. AccuDrive Series S Value engineered and flexible for the Motion Control market S03 S05 S06 S09 S11

- 17. Series S Five Sizes 03, 05, 06, 09, 11 Exact Ratios Backlash as built Metric / Inch shafts Flexible Output Options Hollow, plug-in solid, anti-fretting Designed for growing trend in Packaging for Category 3 machines where an affordable servo rated reducer is preferred.

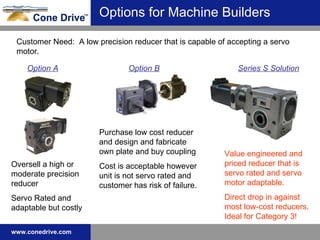

- 18. Options for Machine Builders Customer Need: A low precision reducer that is capable of accepting a servo motor. Option A Option B Oversell a high or moderate precision reducer Servo Rated and adaptable but costly Purchase low cost reducer and design and fabricate own plate and buy coupling Cost is acceptable however unit is not servo rated and customer has risk of failure. Series S Solution Value engineered and priced reducer that is servo rated and servo motor adaptable. Direct drop in against most low-cost reducers. Ideal for Category 3!

- 19. Speed Customer Need: Performance Servo rated up 4,000 RPM Ball Bearings on both the input and output Thermally efficient aluminum housing

- 20. Customer Need: Performance Conex Gearing Industry’s Highest Ratings. Servo Rated. Confidence the product is servo tested – No Guessing.

- 21. Flexibility Standard Hollow Bore Slide in output right or left or double extended. No vents or special oil levels. With or without coupling. Mounts to any servo. Customer Need: Flexibility

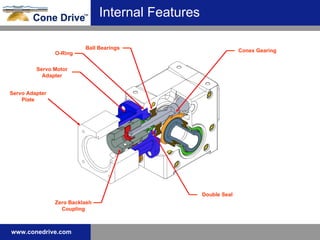

- 22. Internal Features Servo Adapter Plate Zero Backlash Coupling Double Seal Conex Gearing Servo Motor Adapter Ball Bearings O-Ring

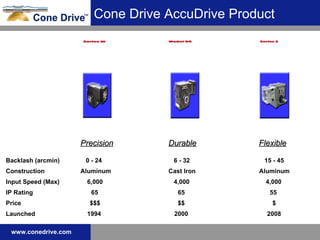

- 23. Cone Drive AccuDrive Product Precision Durable Flexible Backlash (arcmin) Construction Input Speed (Max) IP Rating Price 0 - 24 Aluminum 6,000 65 $$$ 6 - 32 Cast Iron 4,000 65 $$ 15 - 45 Aluminum 4,000 55 $ Launched 1994 2000 2008

- 24. Model HP Servo

- 25. Model HP Servo Adaptation Single Reduction 30 (3.00 inch) 35 (3.50 inch) 40 (4.00 inch) Double Reduction 30-60 / 30-70 35-70 40-80 SPECIFICATIONS Center Distances: 3.00” , 3.50” and 4.00” Servo Motor Frames: Up to 260mm Square Output Torque: Up to 19,160 lb-in (single reduction) Gear Ratios: from 5:1 to 60:1 in single reduction and up to 3,600:1 in double reduction. Multiply levels of backlash from Zero to 15 arcminutes Multiple output options: Solid / Hollow / Shrink Disc

- 26. Servo Gearmotors Series M3 & K3

- 27. NEMA Drives & Gearmotors Double Enveloping Worm Model HP A3 Universal Housing Conex TM Helicoidal Drives Series B Helical Worm Series C (SEW interchange) Shaft Mount Helical Series F (SEW interchange) Helical Bevel Helical Series K (SEW interchange) Inline Helical Series M (SEW interchange)

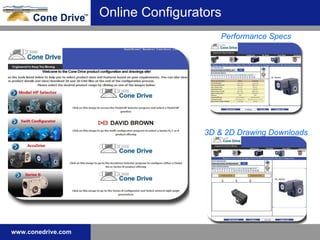

- 28. Online Configurators Performance Specs 3D & 2D Drawing Downloads

- 29. Accudrive full range of products for any packaging machinery needs. Series P & E Model RG Series W Series S Series P & E In-Line Precision or Economical Series W Right Angle High Precision Model RG Right Angle Moderate Precision Series S Right Angle Value-Priced

- 30. Series E Output Flange Options NEMA output Metric D-face C-face drilled and tapped mounting holes Available only for: E 90 E115 ** Pilot Diameter and Bolt Circle Standard Option NEMA Output flanges E 60 NEMA 23 E 90 NEMA 34 & NEMA 42 E115 NEMA 56**

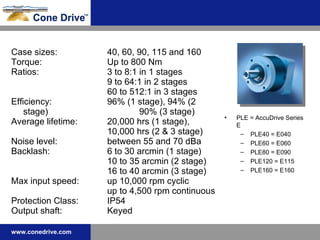

- 31. Series E Case sizes: 40, 60, 90, 115 and 160 Torque: Up to 800 Nm Ratios: 3 to 8:1 in 1 stages 9 to 64:1 in 2 stages 60 to 512:1 in 3 stages Efficiency: 96% (1 stage), 94% (2 stage) 90% (3 stage) Average lifetime: 20,000 hrs (1 stage), 10,000 hrs (2 & 3 stage) Noise level: between 55 and 70 dBa Backlash: 6 to 30 arcmin (1 stage) 10 to 35 arcmin (2 stage) 16 to 40 arcmin (3 stage) Max input speed: up 10,000 rpm cyclic up to 4,500 rpm continuous Protection Class: IP54 Output shaft: Keyed PLE = AccuDrive Series E PLE40 = E040 PLE60 = E060 PLE80 = E090 PLE120 = E115 PLE160 = E160

- 32. New Series P Drop in against Alpha SP+ Accepts larger motor shafts Up 25% increase in torque 50% lower transmission error Up to 15% lighter Increased input speeds New in 2009 Neugart model is PLN used to be called PLS

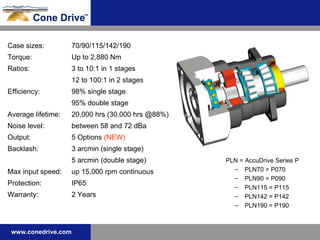

- 33. Series P Case sizes: 70/90/115/142/190 Torque: Up to 2,880 Nm Ratios: 3 to 10:1 in 1 stages 12 to 100:1 in 2 stages Efficiency: 98% single stage 95% double stage Average lifetime: 20,000 hrs (30,000 hrs @88%) Noise level: between 58 and 72 dBa Output: 5 Options (NEW) Backlash: 3 arcmin (single stage) 5 arcmin (double stage) Max input speed: up 15,000 rpm continuous Protection: IP65 Warranty: 2 Years PLN = AccuDrive Series P PLN70 = P070 PLN90 = P090 PLN115 = P115 PLN142 = P142 PLN190 = P190

- 34. Round main body/ring gear housing Output Options: - OP 2: Long pilot (Alpha TP Drop in) OP 5: Spline shaft (DIN 6885 T1) OP 7: Keyed output shaft OP 8: Special shaft OP 14: PLS style (Drop in for old Series P) Neugart Precision Clamping System Viton shaft seals