Gam dyna lite brochure

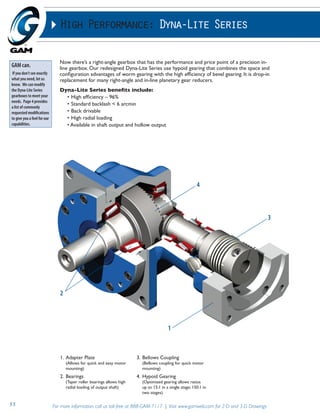

- 1. High Performance: Dyna-Lite Series Now there’s a right-angle gearbox that has the performance and price point of a precision in-line gearbox. Our redesigned Dyna-Lite Series use hypoid gearing that combines the space and configuration advantages of worm gearing with the high efficiency of bevel gearing. It is drop-in replacement for many right-angle and in-line planetary gear reducers. Dyna-Lite Series benefits include: • High efficiency – 96% • Standard backlash < 6 arcmin • Back drivable • High radial loading • Available in shaft output and hollow output 2 1. Adapter Plate (Allows for quick and easy motor mounting) 2. Bearings (Taper roller bearings allows high radial loading of output shaft) 3. Bellows Coupling 4 (Bellows coupling for quick motor mounting) 4. Hypoid Gearing (Optimized gearing allows ratios up to 15:1 in a single stage; 150:1 in two stages) 55 For more information, call us toll-free at 888-GAM-7117 | Visit www.gamweb.com for 2-D and 3-D Drawings 3 1 GAM can. If you don’t see exactly what you need, let us know. We can modify the Dyna-Lite Series gearboxes to meet your needs. Page 4 provides a list of commonly requested modifications to give you a feel for our capabilities.

- 2. High Performance: Dyna-Lite Series DL-DW • Single output shaft configuration with our high performance bellow coupling • Input and housing to mount to any servo motor • Ratios up to 15:1 in a single stage and 150:1 in two stages • Frame sizes: 55, 75 and 90 mm • Drop-in for our highest precision Dyna Series DL-PW • Single output shaft configuration with our high performance bellow coupling • Input and housing to mount to any servo motor • Ratios up to 15:1 in a single stage and 150:1 in two stages • Frame sizes: 55, 75 and 90 mm • Drop-in for many right-angle and in-line planetary gear reducers • Rotation direction is opposite for DW and PW models. DL-PH (Contact GAM for availability) • Smooth hollow output shaft configuration (includes shrink disc) DL-DW High Ratio (High Ratio available on all versions) For more information, call us toll-free at 888-GAM-7117 | Visit www.gamweb.com for 2-D and 3-D Drawings 56 DL-DW DL-PW DL-PH (Available upon request) DL-DH • Smooth hollow output shaft configuration (includes shrink disc) • Input and housing to mount to any servo motor • Ratios up to 15:1 in a single stage and 150:1 in two stages • Frame sizes: 55, 75 and 90 mm • Drop-in for our highest precision Dyna Series DL-DH

- 3. Dyna-Lite Series - DL-D Dyna-Lite Series 55 75 90 Stock Ratios 5, 10, 25, 50, 100, 150 All Ratios Available* 1-stage: 5, 10, 15 2-stage: 25, 50, 100, 150* For other ratios, consult GAM. Nominal Output Torque (T2n) Nm (lb-in) 5:1, 10:1, 25:1, 50:1, 100:1 35 (310) 70 (620) 140 (1239) 15:1, 150:1 25 (221) 50 (443) 90 (797) Max Acceleration Output Torque (T2B) Nm (lb-in) 5:1, 10:1, 25:1, 50:1, 100:1 53 (469) 105 (929) 210 (1859) 15:1, 150:1 38 (336) 75 (664) 143 (1266) Emergency Output Torque (T2not) Nm (lb-in) 5:1, 10:1, 25:1, 50:1, 100:1 70 (620) 140 (1239) 280 (2478) 15:1, 150:1 50 (443) 100 (885) 190 (1682) Nominal Input Speed (n1n) RPM 5:1 3700 3100 2700 10:1, 15:1 4200 3500 3000 2-stage 3500 3000 3000 Max Input Speed (n1max) RPM 6000 6000 5000 Standard Output Backlash (j) arcmin 1-stage < 7 < 7 < 6 2-stage < 9 < 9 < 8 Allowable Radial Load (Frad)1) N (lbs) 3300 (743) 4900 (1103) 7200 (1620) Allowable Axial Load (Faxial) N (lbs) 1650 (371) 2450 (551) 3600 (810) Torsional Stiff ness (Ct21) Nm/arcmin 1.5 4.0 10.0 (lb-in/arcmin) (13.28) (35.40) (88.51) Weight (m) kg (lbs) 1-stage 2.6 (5.7) 4.5 (9.9) 9 (19.8) 2-stage 3.6 (7.9) 6.8 (15) 14.8 (32.6) Noise Level (LPA) dB(A) 1-stage < 66 < 66 < 68 2-stage < 69 < 70 < 72 Mass Moment of Inertia (J1) kg cm2 (lb-in2) 5:1 0.44 (0.15) 1.06 (0.36) 3.6 (1.224) 10:1, 15:1 0.35 (0.119) 0.84 (0.286) 2.9 (0.986) 25:1 0.17 (0.058) 0.45 (0.153) 1.65 (0.561) 50:1, 100:1 0.14 (0.048) 0.34 (0.116) 1.1 (0.374) Effi ciency at Load 5,10: 96% 15: 93% 25,50,100,150: 87% Service Life >15000 hours Lubrication Life Time Lubrication Protection Rating IP 64 Operating Temperature Range -10°C to 100°C (14°F to 212°F) 1) Load applied at center of output shaft @100 RPM * other ratios available 57 For more information, call us toll-free at 888-GAM-7117 | Visit www.gamweb.com for 2-D and 3-D Drawings

- 4. 58 Ø D4 L10 Ø D6 H7 Ø D7 f2 Ø D1 L1 L8 L4 L9 L5 L3 L6 Ø D5 L7 L2 Ø D2 k6 Ø D3 g6 Ø D6 H7 DL-DW DL-DH DL - DW and DL - DH 55 75 90 mm (in) mm (in) mm (in) D1 max (1 stage)* motor shaft diameter 16 (0.63) 20 (0.787) 35 (1.378) D1 max (2 stage standard)* motor shaft diameter 14 (0.551) 19 (0.748) 19 (0.748) D1 max (2 stage available)* motor shaft diameter 16 (0.63) 24 (0.945) 24 (0.945) D2 k6 output shaft diameter 20 (0.787) 24 (0.945) 32 (1.26) D3 g6 pilot diameter 89 (3.504) 105 (4.134) 125 (4.921) D4 bolt circle 110.3 (4.343) 138.6 (5.457) 166.8 (6.567) D5 mounting holes 6.6 (0.26) 9 (0.354) 11 (0.433) D6 H7** hollow bore diameter 20 (0.787) 25 (0.984) 30 (1.181) D7 shrink disc OD (included) 50 (1.97) 60 (2.36) 72 (2.83) L1 1-stage*** gearbox length 175 (6.89) 213.5 (8.406) 257 (10.118) L1 2-stage*** 236 (9.291) 304.5 (11.99) 336 (13.23) L2 shaft length 50.0 (1.969) 55 (2.165) 68 (2.677) L3 fl ange thickness 9 (0.354) 11 (0.433) 14 (0.551) L4 usable shaft length 35 (1.378) 40 (1.575) 50 (1.969) L5 pilot height 13 (0.512) 13 (0.512) 16 (0.63) L6 fl ange size 90 (3.543) 115 (4.528) 140 (5.512) L7 gear off set 9 (0.354) 14 (0.551) 18 (0.709) L8 gearbox width 123 (4.843) 142 (5.591) 175 (6.89) L9 shaft to centerline 87 (3.425) 100 (3.937) 126 (4.961) L10 shrink disc to centerline 64.5 (2.539) 73.5 (2.894) 87 (3.425) f2 shaft thread per DIN332/1 M6 x 16 M8 x 19 M12 x 28 * for larger motor shaft diameters, please contact GAM **mating shaft should have h6 tolerance ***depending on motor, length may vary Recommended Output Coupling (if necessary) metal bellows KLC-50 KLC-125 KM-270 elastomer EKC-80 EKC-110 EKM-300 Tolerances (mm) Size k6 g6 H7 Over 18 +0.015 -0.007 +0.021 Thru 30 +0.002 -0.020 0 Over 30 +0.018 -0.009 +0.025 Thru 50 +0.002 -0.025 0 Over 50 +0.021 -0.010 +0.030 Thru 80 +0.002 -0.029 0 Over 80 +0.025 -0.012 +0.035 Thru 120 +0.003 -0.034 0 Over 120 +0.028 -0.014 +0.040 Thru 180 +0.003 -0.039 0 TYPE CODES FOR DYNA-LITE SERIES (DL-D) Example: DL - DW - 075 - 005 H - [090 - 15A] - S111 Gearbox Series DL = Dyna-Lite Special Options Assigned by GAM Motor Mount Kit Assigned by GAM Gearbox Style DW = shaft output DH = hollow output Gearbox Size 055, 075, 090 Ratio 5, 10, 15, 25, 50, 100 Options Available for This Product G = Keyed output shaft H = Smooth output shaft

- 5. Dyna-Lite Series - DL-P Dyna-Lite Series 55 75 90 Stock Ratios 5, 10, 25, 50, 100, 150 All Ratios Available* 1-stage: 5, 10, 15 2-stage: 25, 50, 100, 150* For other ratios, consult GAM. Nominal Output Torque (T2n) Nm (lb-in) 5:1, 10:1, 25:1, 50:1, 100:1 35 (310) 70 (620) 140 (1239) 15:1, 150:1 25 (221) 50 (443) 90 (797) Max Acceleration Output Torque (T2B) Nm (lb-in) 5:1, 10:1, 25:1, 50:1, 100:1 53 (469) 105 (929) 210 (1859) 15:1, 150:1 38 (336) 75 (664) 143 (1266) Emergency Output Torque (T2not) Nm (lb-in) 5:1, 10:1, 25:1, 50:1, 100:1 70 (620) 140 (1239) 280 (2478) 15:1, 150:1 50 (443) 100 (885) 190 (1682) Nominal Input Speed (n1n) RPM 5:1 3700 3100 2700 10:1, 15:1 4200 3500 3000 2-stage 3500 3000 3000 Max Input Speed (n1max) RPM 6000 6000 5000 Standard Output Backlash (j) arcmin 1-stage < 7 < 7 < 6 2-stage < 9 < 9 < 8 Allowable Radial Load (Frad)1) N (lbs) 2200 (495) 4050 (911) 6200 (1395) Allowable Axial Load (Faxial) N (lbs) 1100 (248) 2025 (456) 3100 (698) Torsional Stiff ness (Ct21) Nm/arcmin 1.5 4.0 10.0 (lb-in/arcmin) (13.28) (35.40) (88.51) Weight (m) kg (lbs) 1-stage 2.6 (5.7) 4.5 (9.9) 9 (19.8) 2-stage 3.6 (7.9) 6.8 (15) 14.8 (32.6) Noise Level (LPA) dB(A) 1-stage < 66 < 66 < 68 2-stage < 69 < 70 < 72 Mass Moment of Inertia (J1) kg cm2 (lb-in2) 5:1 0.44 (0.15) 1.08 (0.37) 3.7 (1.258) 10:1, 15:1 0.35 (0.119) 0.84 (0.286) 2.9 (0.986) 25:1 0.17 (0.058) 0.45 (0.153) 1.65 (0.561) 50:1, 100:1 0.14 (0.048) 0.34 (0.116) 1.1 (0.374) Effi ciency at Load 5,10: 96% 15: 93% 25,50,100,150: 87% Service Life >15000 hours Lubrication Life Time Lubrication Protection Rating IP 64 Operating Temperature Range -10°C to 100°C (14°F to 212°F) 1) Load applied at center of output shaft @100 RPM * other ratios available 59 For more information, call us toll-free at 888-GAM-7117 | Visit www.gamweb.com for 2-D and 3-D Drawings

- 6. 60 L3 I.M.P.A.C.T.® Series - JPG-W DL-PW L8 Ø D6 H7 Recommended Output Coupling (if necessary) metal bellows KLC-50 KLC-125 KM-270 elastomer EKC-80 EKC-110 EKM-300 Tolerances (mm) Size k6 g6 H7 Over 18 +0.015 -0.007 +0.021 Thru 30 +0.002 -0.020 0 Over 30 +0.018 -0.009 +0.025 Thru 50 +0.002 -0.025 0 Over 50 +0.021 -0.010 +0.030 Thru 80 +0.002 -0.029 0 Over 80 +0.025 -0.012 +0.035 Thru 120 +0.003 -0.034 0 Over 120 +0.028 -0.014 +0.040 Thru 180 +0.003 -0.039 0 TYPE CODES FOR DYNA-LITE SERIES (DL-P) Example: DL - PW - 075 - 005 H - [090 - 15A] - S111 Gearbox Series DL = Dyna-Lite Special Options Assigned by GAM Motor Mount Kit Assigned by GAM Gearbox Style PW = shaft output PH = hollow output Gearbox Size 055, 075, 090 Ratio 5, 10, 15, 25, 50, 100 Options Available for This Product G = Keyed output shaft H = Smooth output shaft Ø D1 L7 Ø D5 L6 Ø D3 g6 L4 L2 L5 L1 Ø D4 Ø D2 k6 DL-PH Ø D6 H7 Ø D7 L11 L10 f2 DL - PW and DL - PH 55 75 90 mm (in) mm (in) mm (in) D1 max (1 stage)* motor shaft diameter 16 (0.63) 20 (0.787) 35 (1.378) D1 max (2 stage standard)* motor shaft diameter 14 (0.551) 19 (0.748) 19 (0.748) D1 max (2 stage available)* motor shaft diameter 16 (0.63) 24 (0.945) 24 (0.945) D2 k6 output shaft diameter 16 (0.63) 22 (0.866) 32 (1.26) D3 g6 pilot diameter 60 (2.362) 70 (2.756) 90 (3.543) D4 bolt circle 68 (2.677) 85 (3.346) 120 (4.724) D5 mounting holes 5.5 (0.217) 6.6 (0.26) 9 (0.354) D6 H7** hollow bore diameter 15 (0.591) 20 (0.787) 30 (1.181) D7 shrink disc OD (included) 44 (1.732) 50 (1.969) 72 (2.835) L1 1-stage*** gearbox length 172 (6.772) 206 (8.11) 249.5 (9.823) L1 2-stage*** 236 (9.291) 304.5 (11.99) 336 (13.23) L2 shaft length 48.0 (1.89) 56 (2.205) 80 (3.15) L3 fl ange thickness 8.5 (0.335) 10 (0.394) 13 (0.512) L4 usable shaft length 28 (1.102) 36 (1.417) 58 (2.283) L5 pilot height 18 (0.709) 18 (0.709) 20 (0.787) L6 fl ange size 66 (2.598) 76 (2.992) 101 (3.976) L7 gear off set 9 (0.354) 14 (0.551) 18 (0.709) L8 gearbox width 141.5 (5.571) 166 (6.535) 216 (8.504) L10 shaft to centerline 95 (3.740) 110 (4.331) 148 (5.827) L11 shrink disc to centerline estimated 70 (2.756) estimated 86 (3.386) estimated 108 (4.252) F2 shaft thread per DIN332/1 M6 x 16 M8 x 19 M12x28 * for larger motor shaft diameters, please contact GAM **mating shaft should have h6 tolerance ***depending on motor, length may vary

![58

Ø D4

L10

Ø D6 H7

Ø D7

f2

Ø D1

L1

L8

L4

L9

L5 L3

L6

Ø D5

L7

L2

Ø D2 k6

Ø D3 g6

Ø D6 H7

DL-DW DL-DH

DL - DW and DL - DH

55 75 90

mm (in) mm (in) mm (in)

D1 max (1 stage)* motor shaft diameter 16 (0.63) 20 (0.787) 35 (1.378)

D1 max (2 stage standard)* motor shaft diameter 14 (0.551) 19 (0.748) 19 (0.748)

D1 max (2 stage available)* motor shaft diameter 16 (0.63) 24 (0.945) 24 (0.945)

D2 k6 output shaft diameter 20 (0.787) 24 (0.945) 32 (1.26)

D3 g6 pilot diameter 89 (3.504) 105 (4.134) 125 (4.921)

D4 bolt circle 110.3 (4.343) 138.6 (5.457) 166.8 (6.567)

D5 mounting holes 6.6 (0.26) 9 (0.354) 11 (0.433)

D6 H7** hollow bore diameter 20 (0.787) 25 (0.984) 30 (1.181)

D7 shrink disc OD (included) 50 (1.97) 60 (2.36) 72 (2.83)

L1 1-stage***

gearbox length

175 (6.89) 213.5 (8.406) 257 (10.118)

L1 2-stage*** 236 (9.291) 304.5 (11.99) 336 (13.23)

L2 shaft length 50.0 (1.969) 55 (2.165) 68 (2.677)

L3 fl ange thickness 9 (0.354) 11 (0.433) 14 (0.551)

L4 usable shaft length 35 (1.378) 40 (1.575) 50 (1.969)

L5 pilot height 13 (0.512) 13 (0.512) 16 (0.63)

L6 fl ange size 90 (3.543) 115 (4.528) 140 (5.512)

L7 gear off set 9 (0.354) 14 (0.551) 18 (0.709)

L8 gearbox width 123 (4.843) 142 (5.591) 175 (6.89)

L9 shaft to centerline 87 (3.425) 100 (3.937) 126 (4.961)

L10 shrink disc to centerline 64.5 (2.539) 73.5 (2.894) 87 (3.425)

f2 shaft thread per DIN332/1 M6 x 16 M8 x 19 M12 x 28

* for larger motor shaft diameters, please contact GAM **mating shaft should have h6 tolerance ***depending on motor, length may vary

Recommended Output Coupling (if necessary)

metal bellows

KLC-50 KLC-125 KM-270

elastomer

EKC-80 EKC-110 EKM-300

Tolerances (mm)

Size k6 g6 H7

Over 18 +0.015 -0.007 +0.021

Thru 30 +0.002 -0.020 0

Over 30 +0.018 -0.009 +0.025

Thru 50 +0.002 -0.025 0

Over 50 +0.021 -0.010 +0.030

Thru 80 +0.002 -0.029 0

Over 80 +0.025 -0.012 +0.035

Thru 120 +0.003 -0.034 0

Over 120 +0.028 -0.014 +0.040

Thru 180 +0.003 -0.039 0

TYPE CODES FOR DYNA-LITE SERIES (DL-D)

Example: DL - DW - 075 - 005 H - [090 - 15A] - S111

Gearbox Series

DL = Dyna-Lite

Special Options

Assigned by GAM

Motor Mount Kit

Assigned by GAM

Gearbox Style

DW = shaft output

DH = hollow output

Gearbox Size

055, 075, 090

Ratio

5, 10, 15, 25, 50, 100

Options Available for This Product

G = Keyed output shaft

H = Smooth output shaft](https://image.slidesharecdn.com/gamdynalitebrochure-141001201140-phpapp02/85/Gam-dyna-lite-brochure-4-320.jpg)

![60

L3

I.M.P.A.C.T.® Series - JPG-W

DL-PW

L8

Ø D6 H7

Recommended Output Coupling (if necessary)

metal bellows

KLC-50 KLC-125 KM-270

elastomer

EKC-80 EKC-110 EKM-300

Tolerances (mm)

Size k6 g6 H7

Over 18 +0.015 -0.007 +0.021

Thru 30 +0.002 -0.020 0

Over 30 +0.018 -0.009 +0.025

Thru 50 +0.002 -0.025 0

Over 50 +0.021 -0.010 +0.030

Thru 80 +0.002 -0.029 0

Over 80 +0.025 -0.012 +0.035

Thru 120 +0.003 -0.034 0

Over 120 +0.028 -0.014 +0.040

Thru 180 +0.003 -0.039 0

TYPE CODES FOR DYNA-LITE SERIES (DL-P)

Example: DL - PW - 075 - 005 H - [090 - 15A] - S111

Gearbox Series

DL = Dyna-Lite

Special Options

Assigned by GAM

Motor Mount Kit

Assigned by GAM

Gearbox Style

PW = shaft output

PH = hollow output

Gearbox Size

055, 075, 090

Ratio

5, 10, 15, 25, 50, 100

Options Available for This Product

G = Keyed output shaft

H = Smooth output shaft

Ø D1

L7

Ø D5

L6

Ø D3 g6

L4

L2

L5

L1

Ø D4

Ø D2 k6

DL-PH

Ø D6 H7

Ø D7

L11

L10

f2

DL - PW and DL - PH

55 75 90

mm (in) mm (in) mm (in)

D1 max (1 stage)* motor shaft diameter 16 (0.63) 20 (0.787) 35 (1.378)

D1 max (2 stage standard)* motor shaft diameter 14 (0.551) 19 (0.748) 19 (0.748)

D1 max (2 stage available)* motor shaft diameter 16 (0.63) 24 (0.945) 24 (0.945)

D2 k6 output shaft diameter 16 (0.63) 22 (0.866) 32 (1.26)

D3 g6 pilot diameter 60 (2.362) 70 (2.756) 90 (3.543)

D4 bolt circle 68 (2.677) 85 (3.346) 120 (4.724)

D5 mounting holes 5.5 (0.217) 6.6 (0.26) 9 (0.354)

D6 H7** hollow bore diameter 15 (0.591) 20 (0.787) 30 (1.181)

D7 shrink disc OD (included) 44 (1.732) 50 (1.969) 72 (2.835)

L1 1-stage***

gearbox length

172 (6.772) 206 (8.11) 249.5 (9.823)

L1 2-stage*** 236 (9.291) 304.5 (11.99) 336 (13.23)

L2 shaft length 48.0 (1.89) 56 (2.205) 80 (3.15)

L3 fl ange thickness 8.5 (0.335) 10 (0.394) 13 (0.512)

L4 usable shaft length 28 (1.102) 36 (1.417) 58 (2.283)

L5 pilot height 18 (0.709) 18 (0.709) 20 (0.787)

L6 fl ange size 66 (2.598) 76 (2.992) 101 (3.976)

L7 gear off set 9 (0.354) 14 (0.551) 18 (0.709)

L8 gearbox width 141.5 (5.571) 166 (6.535) 216 (8.504)

L10 shaft to centerline 95 (3.740) 110 (4.331) 148 (5.827)

L11 shrink disc to centerline estimated 70 (2.756) estimated 86 (3.386) estimated 108 (4.252)

F2 shaft thread per DIN332/1 M6 x 16 M8 x 19 M12x28

* for larger motor shaft diameters, please contact GAM **mating shaft should have h6 tolerance ***depending on motor, length may vary](https://image.slidesharecdn.com/gamdynalitebrochure-141001201140-phpapp02/85/Gam-dyna-lite-brochure-6-320.jpg)