Armstrong safety1

- 1. Industrial Hand Tool Safety Training Program Form No. 89081-32

- 2. Goals for a productive and healthy work environment: • Reduce workplace accidents and musculoskeletal disorders • Reduce downtime • Increase productivity • Improve job satisfaction This program will help you learn how to: • Select the right tool for the job • Use it correctly • Identify safety rules and solutions for each tool Safety Training from Armstrong

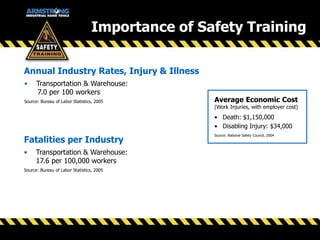

- 3. • Transportation & Warehouse: 7.0 per 100 workers Source: Bureau of Labor Statistics, 2005 Annual Industry Rates, Injury & Illness • Transportation & Warehouse: 17.6 per 100,000 workers Source: Bureau of Labor Statistics, 2005 Fatalities per Industry Average Economic Cost (Work Injuries, with employer cost) • Death: $1,150,000 • Disabling Injury: $34,000 Source: National Safety Council, 2004 Importance of Safety Training

- 4. • Musculoskeletal disorders (or MSDs) affect the muscles, nerves, tendons, ligaments, joints, and spinal discs, and are commonly caused by repetitive forceful exertions, reaching, and awkward positions. • OSHA reports MSDs are the single largest occupational safety and health problem in the U.S., a third of all lost workday cases, causing 1.8 million injuries each year. • The use of ergonomic solutions in the workplace, OSHA states, would reduce claims by 250,000 each year, saving companies millions in workers compensation, lost productivity, rehiring, retraining, and overtime. MSDs: A Common Overuse Injury Importance of Safety Training

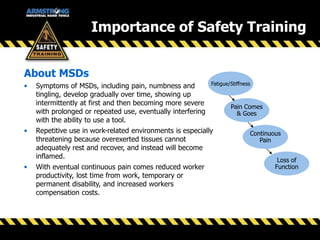

- 5. • Symptoms of MSDs, including pain, numbness and tingling, develop gradually over time, showing up intermittently at first and then becoming more severe with prolonged or repeated use, eventually interfering with the ability to use a tool. • Repetitive use in work-related environments is especially threatening because overexerted tissues cannot adequately rest and recover, and instead will become inflamed. • With eventual continuous pain comes reduced worker productivity, lost time from work, temporary or permanent disability, and increased workers compensation costs. About MSDs Fatigue/Stiffness Pain Comes & Goes Continuous Pain Loss of Function Importance of Safety Training

- 6. Ergonomic hand tool design goals include developing tools that: • Require less force or grip strength • Allow for correct body alignment • Reduce repetitive motion activities How Design Helps Reduce Ergonomic Hazards Bend the tool, not the wrist. Reducing Ergonomic Hazards

- 7. • Fit the task being performed • Fit the user’s hand, with tool’s center of gravity aligned with the center of gripping hand • Reduce the force being applied • Allow the wrist position to remain neutral when in use The Right Tool Should… Reducing Ergonomic Hazards

- 8. 1. Use hand tools properly, as they are designed to be used. 2. Properly inspect and maintain your tools. 3. Wear effective eye and ear protection. 4. Do not wear loose fitting clothing. 5. Select the right tool for the job. 6. Wear steel toed shoes. 7. Remove all jewelry. General Safety Tips: General Safety Tips

- 9. 1. Sockets 2. Ratchets 3. Wrenches 4. Torque Tools 5. Striking and Struck Tools 6. Screwdrivers 7. Pliers 8. Tool Storage Review 7 Hand Tool Categories: Training Objectives for Each Section: 1. Describe the tools, 2. Understand proper usage, and 3. Identify safety rules and solutions What We’ll Cover

- 10. Sockets 6 pt. Sockets → hex fasteners 12 pt. Sockets → hex or 12 pt. fasteners • Universals – Hand and impact sockets, used with tools where you need more access • Power – Used with power and air tools only - black oxide finish • Impact Locking Extensions – Used with impact tools • Impact – Used with impact tools - black oxide finish • Hand – Used with hand tools only – chrome finish Hand Socket Power SocketImpact Socket Impact Locking Extension Cold- formed ball recess design for tight fit Universal Impact Socket Sockets

- 11. Useful Tips • Choose sockets that are clearly marked, to be read even in low light conditions • When using an impact extension, be sure to use one that securely locks in place. Sockets

- 12. • Never choose a socket that improperly fits the fastener. • Never use a socket that is cracked or shows excessive signs of wear. • Select the proper socket for the job. • Never hold an impact socket in your hand when in use. • Never assume an impact socket is properly attached to a drive tool. • Never use a hand or power socket on an impact wrench. Only use an impact socket. Safety Rules & Solutions Sockets

- 13. Ratchets Use with hand sockets, available in variety of drive sizes and styles • Tear Drop – Most popular, greatest versatility in ratcheting angle, size and strength • Round head – Ratcheting angle great for use in confined areas • Specialty – Scaffold, Spud, Flex Head, Long Handle and others Round Head Tear Drop Flex Head Long Handle Spud RatchetScaffold Ratchet Ratchets

- 14. Useful Tips • Ratchet drive sizes range from ¼” to 1-1/2” drive sizes. Always choose the proper drive size for the fastener. • Never adapt up or down more than one size. • Always inspect and clean ratchets before use, making sure they are free from damage and dirt. Replace any worn components. • When you need more access, choose a flex head ratchet with a locking mechanism; this locks the ratchet head in position under load, an important safety practice. Ratchets

- 15. • Use a ratchet designed for the job. • Never use a cheater or extender and never strike a ratchet head or handle. • Never push a ratchet. Always pull to maintain your balance. • Never use a ratchet with worn or dirty components. Clean or replace them. Safety Rules & Solutions Ratchets

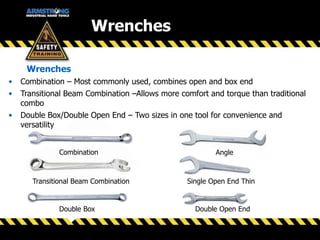

- 16. Wrenches • Combination – Most commonly used, combines open and box end • Transitional Beam Combination –Allows more comfort and torque than traditional combo • Double Box/Double Open End – Two sizes in one tool for convenience and versatility Wrenches Transitional Beam Combination Combination Double Box Angle Single Open End Thin Double Open End

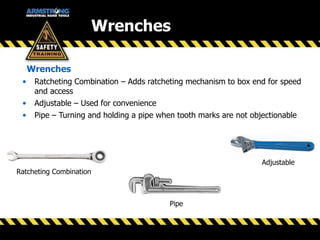

- 17. Wrenches • Ratcheting Combination – Adds ratcheting mechanism to box end for speed and access • Adjustable – Used for convenience • Pipe – Turning and holding a pipe when tooth marks are not objectionable Wrenches Ratcheting Combination Adjustable Pipe

- 18. Wrenches Useful Tips • Use the box end for final tightening or breaking a fastener. There’s much less chance of a box end slipping off a fastener and causing injury because it contacts the fastener on all sides. • Always tighten the adjustable jaw against the fastener, and always pull toward you with the force on the fixed jaw. • Vinyl grips do not provide any protection against electrical shock. • When using a wrench, keep your wrist straight. Choose a wrench that allows you to maintain a neutral wrist position. And choose a wrench that allows you to always put the flat of the beam in the palm of your hand to reduce the risk of long-term injury.

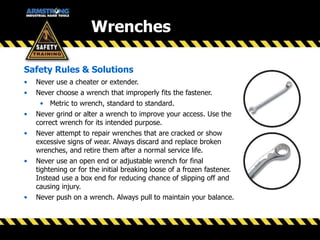

- 19. Safety Rules & Solutions Wrenches • Never use a cheater or extender. • Never choose a wrench that improperly fits the fastener. • Metric to wrench, standard to standard. • Never grind or alter a wrench to improve your access. Use the correct wrench for its intended purpose. • Never attempt to repair wrenches that are cracked or show excessive signs of wear. Always discard and replace broken wrenches, and retire them after a normal service life. • Never use an open end or adjustable wrench for final tightening or for the initial breaking loose of a frozen fastener. Instead use a box end for reducing chance of slipping off and causing injury. • Never push on a wrench. Always pull to maintain your balance.

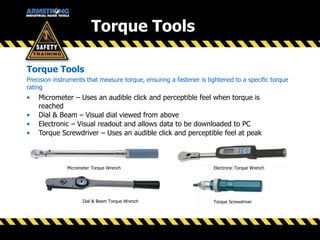

- 20. Torque Tools Precision instruments that measure torque, ensuring a fastener is tightened to a specific torque rating • Micrometer – Uses an audible click and perceptible feel when torque is reached • Dial & Beam – Visual dial viewed from above • Electronic – Visual readout and allows data to be downloaded to PC • Torque Screwdriver – Uses an audible click and perceptible feel at peak Torque Tools Micrometer Torque Wrench Dial & Beam Torque Wrench Torque Screwdriver Electronic Torque Wrench

- 21. Useful Tips • With a micrometer torque wrench, the “click” sound indicates the fastener has reached the correct torque level. This is your indicator to stop pulling on the torque wrench. • Micrometer torque wrenches should not be used to break loose a fastener. Instead use a box wrench or socket and ratchet combination. • Be sure you follow all the safety tips previously covered under hand sockets when using a micrometer torque wrench. • Use smooth, consistent pulling motion when using the torque wrench until the appropriate torque is reached. • Recalibrate your torque wrench frequently so it is properly maintained and always ready for use. • Torque wrenches are high precision instruments; handle with care. Torque Tools

- 22. Safety Rules & Solutions • Never use a cheater or extender or exceed the rated capacity of the torque wrench. Select the product with the correct capacity. • Never over tighten fasteners when using micrometer wrenches. Release the pressure as soon as the click is heard. • Never push on a torque wrench. Always pull to maintain balance. • Never use the torque wrench for any other application other than final torquing; e.g. do not drop, throw, use as a hammer, or breaker bar. Torque Tools

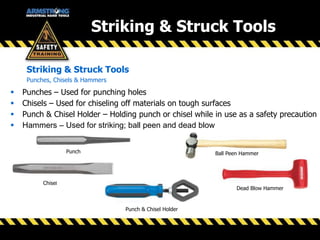

- 23. Striking & Struck Tools Striking & Struck Tools Punches, Chisels & Hammers Punches – Used for punching holes Chisels – Used for chiseling off materials on tough surfaces Punch & Chisel Holder – Holding punch or chisel while in use as a safety precaution Hammers – Used for striking; ball peen and dead blow Punch Chisel Ball Peen Hammer Dead Blow Hammer Punch & Chisel Holder

- 24. Striking & Struck Tools Useful Tips • Eye protection is a must whenever you are working with striking or struck tools. • Punches and chisels should be inspected regularly. • Consider using punch or chisel with a parabolic head, which directs the striking force to the center of the tool for less chipping and mushrooming. • To effectively reduce injuries, always use a punch and chisel holder. A V-notch provides extra security minimizing slippage and injuries.

- 25. Striking & Struck Tools • Always use a Ball Peen hammer on a punch or chisel. • Never use a hammer with a cracked or damaged handle or loose hammer head. Inspect regularly and replace damaged hammers. • Never strike a ball peen hammer against material of equal or greater hardness, especially one ball peen hammer with another hammer. Select the proper hammer for the job. • Never select an over or under sized hammer. Use one with a striking face 3/8” larger than the face of the struck tools. • Always wear the appropriate eye protection. Safety Rules & Solutions - Hammers

- 26. Striking & Struck Tools • Never hold a punch or chisel in your hand. Always use a punch and chisel holder. • Inspect and maintain your punch and chisel tools. • Never place your hands in front of a cutting edge. Always secure the material being worked with a clamp. • Always wear the appropriate eye protection. Safety Rules & Solutions – Punches & Chisels

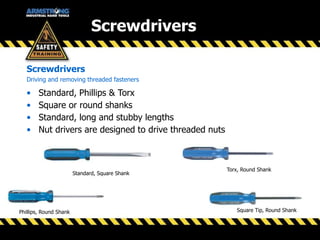

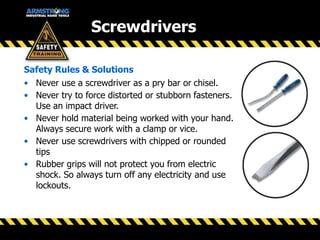

- 27. Screwdrivers Screwdrivers Driving and removing threaded fasteners • Standard, Phillips & Torx • Square or round shanks • Standard, long and stubby lengths • Nut drivers are designed to drive threaded nuts Standard, Square Shank Phillips, Round Shank Square Tip, Round Shank Torx, Round Shank

- 28. Screwdrivers Useful Tips Choose screwdrivers with a large handle (preferably 4 to 6 inches long and 1-1/4 to 2 inches in diameter). Select an extruded, tri-oval shaped handle that will conform to your hand, for a more comfortable grip. To remove stubborn fasteners, an impact driver. Hold your work with a vice. Slipping with a screwdriver can cause serious injury. Always match the tip of your screwdriver with the fastener. Using a tip that is too large or too small can lead to potential injuries as well as damage to the fastener Don’t redress. It can change the strength characteristics of the metal.

- 29. Screwdrivers Safety Rules & Solutions • Never use a screwdriver as a pry bar or chisel. • Never try to force distorted or stubborn fasteners. Use an impact driver. • Never hold material being worked with your hand. Always secure work with a clamp or vice. • Never use screwdrivers with chipped or rounded tips • Rubber grips will not protect you from electric shock. So always turn off any electricity and use lockouts.

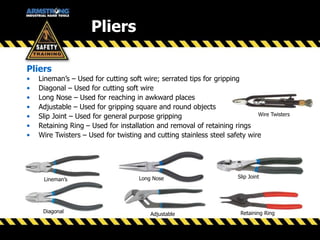

- 30. Pliers Pliers • Lineman’s – Used for cutting soft wire; serrated tips for gripping • Diagonal – Used for cutting soft wire • Long Nose – Used for reaching in awkward places • Adjustable – Used for gripping square and round objects • Slip Joint – Used for general purpose gripping • Retaining Ring – Used for installation and removal of retaining rings • Wire Twisters – Used for twisting and cutting stainless steel safety wire Lineman’s Diagonal Adjustable Long Nose Slip Joint Retaining Ring Wire Twisters

- 31. Pliers Useful Tips • Pliers come in a variety of sizes and styles. Carry a wide selection of pliers and take time to select the right tool for your job. • When using retaining ring pliers, use the proper sized pliers that best fit the holes in the retaining ring.

- 32. Pliers Safety Rules & Solutions • Never use a pair of pliers to strike anything. Use the appropriate striking tool. • Never rock pliers to complete a cut. Choose a larger pair, or use high leverage long reach pliers. Always cut at right angles. • Never use pliers to hold nuts and bolts. Use the appropriate socket or wrench. • Never use worn, cracked, broken or sprung pliers • Rubber grips will not protect you from electric shock. So always turn off any electricity and use lockouts.

- 33. Tool Storage Tool Storage • Mobile – Roller cabinets are large, moving tool storage units • Stationary – Top chests are generally added to mobile rolling cabinets for additional storage capacity

- 34. Tool Storage Safety Rules & Solutions - Tool Storage • Never over-crowd your tools in a storage cabinet. This could cause an over-load condition. • Never leave your cabinet unlocked when moving it. Lock all drawers to prevent drawers from suddenly opening while in motion, which could cause the cabinet to get off balance and tip. • Never open more than one drawer at a time. • Always push so you can see the direction you are traveling and avoid collisions. • Always make sure the brakes on your casters are set so the box doesn’t drift and cause damage to other equipment.