Rapid construction techniques

- 1. RAPID CONSTRUCTION TECHNIQUES Adoption of new technology For construction practice BUILDING ENGINEERING AND MANAGEMENT Construction Management Tool and Technique [MBEM -112] Deepak Pradhan 1210900048

- 2. IN GENERAL OUR CONSTRUCTION INDUSTRY DON’T INCORPORATE NEW TECHNOLOGY THAT QUICK. But, Prefabrication is already becoming more common. • "The benefits are quick to see and identify, Climate control, Safety, Available equipment. • It helps the contractor to control the schedule a little bit better and the quality as well." INTRODUCTION WHY WE NEED RAPID CONSTRUCTION TECHNIQUES? Construction industries faces lots of ongoing challenges of maintaining, rehabilitating, expenditures and many more. All these things are directly connected to the time, as the time increases it may lead to increase in challenges or problems which will lead us to Rework and as we all have budget constraints that’s why the main target is to MINIMIZE THE CONSTRUCTION TIME. To complete the work without compromising the quality and in a time frame with minimal impact on public. Also there are many advances of using rapid constructions. reduce congestion associated in the construction flow. Construction practice Challenges / problems Re work Increase in time frame Increase in budget Compromise with Quality Client un-satisfaction Introducing new Technology -with unskilled labor

- 3. MAJOR TYPES OF RAPID CONSTRUCTION PRACTICE : 1. Pre-fabricated sandwich panel system 2. Monolithic Concrete Construction ( mivan shuttering ) 3. Precast Concrete Construction System – Precast Components Assembled at Site 4. Precast Concrete Construction System – 3D Volumetric 5. Light Gauge Steel Structural System & Pre-engineered Steel Structural System (LGSF) 6. PVC Stay In Place Formwork System Construction practice New technology with skilled labor and machine New technology which doesn't require skilled labor or minimize the size of labor Increase in one time cost Completion in time Client satisfaction The main aim is to place a greater emphasis on achieving a better construction technology which meets the needs of the end user at the earliest possible.

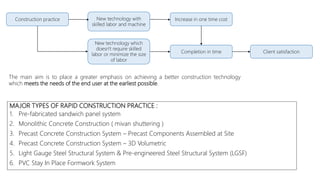

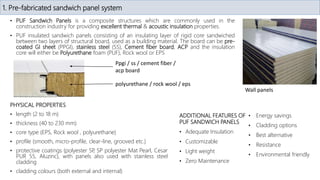

- 4. 1. Pre-fabricated sandwich panel system PHYSICAL PROPERTIES • length (2 to 18 m) • thickness (40 to 230 mm) • core type (EPS, Rock wool , polyurethane) • profile (smooth, micro-profile, clear-line, grooved etc.) • protective coatings (polyester SP , SP polyester Mat Pearl, Cesar PUR 55, Aluzinc), with panels also used with stainless steel cladding • cladding colours (both external and internal) • PUF Sandwich Panels is a composite structures which are commonly used in the construction industry for providing excellent thermal & acoustic insulation properties. • PUF insulated sandwich panels consisting of an insulating layer of rigid core sandwiched between two layers of structural board, used as a building material. The board can be pre- coated GI sheet (PPGI), stainless steel (SS), Cement fiber board, ACP and the insulation core will either be Polyurethane foam (PUF), Rock wool or EPS ADDITIONAL FEATURES OF PUF SANDWICH PANELS • Adequate Insulation • Customizable • Light weight • Zero Maintenance • Energy savings • Cladding options • Best alternative • Resistance • Environmental friendly Ppgi / ss / cement fiber / acp board polyurethane / rock wool / eps Wall panels

- 5. These replace conventional brick & mortar walling construction practices and can be used as load-bearing and non-load bearing walling for residential and commercial buildings. For buildings higher than single storey, the system can be used either with RCC or steel framed structure. In this system the EPS Cement Panels are manufactured at the factory in controlled condition, which are then dispatched to the site. The panels having tongue and groove are joint together for construction of the building. SPECIAL FEATURES: • Being dry walling system, brings speed in construction, water conservation (no use of water for curing of walling components at site). • The sandwich panels have light weight material as core material, which brings resource efficiency, better thermal insulation, acoustics & energy efficiency. • Being light in weight results in lower dead load of building, decrease in foundation size and steal count • Save between 2% of floor space and 40%-50% heat and cooling cost . Tongue and groove are joint Corner joint Roof panel joinery detail

- 6. Cement board puff- panel flooring Ppgi sheet puff- panel roof Acp sheet puff- wall panel Steel skeleton structure ready for the installation of wall panels

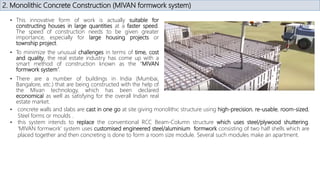

- 8. 2. Monolithic Concrete Construction (MIVAN formwork system) • This innovative form of work is actually suitable for constructing houses in large quantities at a faster speed. The speed of construction needs to be given greater importance, especially for large housing projects or township project. • To minimize the unusual challenges in terms of time, cost and quality, the real estate industry has come up with a smart method of construction known as the “MIVAN formwork system”. • There are a number of buildings in India (Mumbai, Bangalore, etc.) that are being constructed with the help of the Mivan technology, which has been declared economical as well as satisfying for the overall Indian real estate market. • concrete walls and slabs are cast in one go at site giving monolithic structure using high-precision, re-usable, room-sized, Steel forms or moulds . • this system intends to replace the conventional RCC Beam-Column structure which uses steel/plywood shuttering. ‘MIVAN formwork’ system uses customised engineered steel/aluminium formwork consisting of two half shells which are placed together and then concreting is done to form a room size module. Several such modules make an apartment.

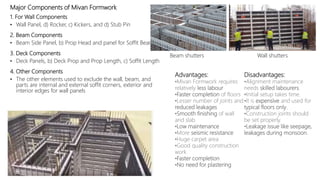

- 9. Major Components of Mivan Formwork 1. For Wall Components • Wall Panel, d) Rocker, c) Kickers, and d) Stub Pin 2. Beam Components • Beam Side Panel, b) Prop Head and panel for Soffit Beam 3. Deck Components • Deck Panels, b) Deck Prop and Prop Length, c) Soffit Length 4. Other Components • The other elements used to exclude the wall, beam, and parts are internal and external soffit corners, exterior and interior edges for wall panels Beam shutters Wall shutters Advantages: •Mivan Formwork requires relatively less labour •Faster completion of floors •Lesser number of joints and reduced leakages •Smooth finishing of wall and slab •Low maintenance •More seismic resistance •Huge carpet area •Good quality construction work •Faster completion •No need for plastering Disadvantages: •Alignment maintenance needs skilled labourers. •Initial setup takes time. •It is expensive and used for typical floors only. •Construction joints should be set properly. •Leakage issue like seepage, leakages during monsoon.

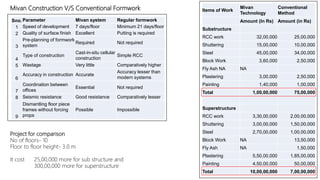

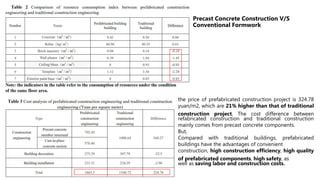

- 10. Sno. Parameter Mivan system Regular formwork 1 Speed of development 7 days/floor Minimum 21 days/floor 2 Quality of surface finish Excellent Putting is required 3 Pre-planning of formwork system Required Not required 4 Type of construction Cast-in-situ cellular construction Simple RCC 5 Wastage Very little Comparatively higher 6 Accuracy in construction Accurate Accuracy lesser than modern systems 7 Coordination between offices Essential Not required 8 Seismic resistance Good resistance Comparatively lesser 9 Dismantling floor piece frames without forcing props Possible Impossible Mivan Construction V/S Conventional Formwork Project for comparison No of floors- 10 Floor to floor height- 3.0 m It cost 25,00,000 more for sub structure and 300,00,000 more for superstructure Items of Work Mivan Technology Conventional Method Amount (In Rs) Amount (in Rs) Substructure RCC work 32,00,000 25,00,000 Shuttering 15,00,000 10,00,000 Steel 45,00,000 34,00,000 Block Work 3,60,000 2,50,000 Fly Ash NA NA Plastering 3,00,000 2,50,000 Painting 1,40,000 1,00,000 Total 1,00,00,000 75,00,000 Superstructure RCC work 3,30,00,000 2,00,00,000 Shuttering 3,00,00,000 1,50,00,000 Steel 2,70,00,000 1,00,00,000 Block Work NA 13,50,000 Fly Ash NA 1,50,000 Plastering 5,50,00,000 1,85,00,000 Painting 4,50,00,000 50,00,000 Total 10,00,00,000 7,00,00,000

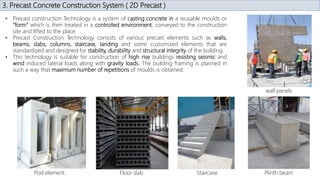

- 13. 3. Precast Concrete Construction System ( 2D Precast ) • Precast construction Technology is a system of casting concrete in a reusable moulds or “form” which is then treated in a controlled environment, conveyed to the construction site and lifted to the place. • Precast Construction Technology consists of various precast elements such as walls, beams, slabs, columns, staircase, landing and some customized elements that are standardized and designed for stability, durability and structural integrity of the building. • This technology is suitable for construction of high rise buildings resisting seismic and wind induced lateral loads along with gravity loads. The building framing is planned in such a way that maximum number of repetitions of moulds is obtained. wall panels Plinth beam Staircase Floor slab Pod element

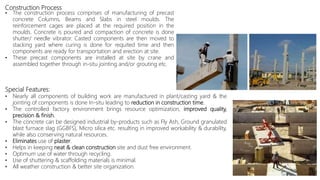

- 14. Construction Process • The construction process comprises of manufacturing of precast concrete Columns, Beams and Slabs in steel moulds. The reinforcement cages are placed at the required position in the moulds. Concrete is poured and compaction of concrete is done shutter/ needle vibrator. Casted components are then moved to stacking yard where curing is done for requited time and then components are ready for transportation and erection at site. • These precast components are installed at site by crane and assembled together through in-situ jointing and/or grouting etc. Special Features: • Nearly all components of building work are manufactured in plant/casting yard & the jointing of components is done In-situ leading to reduction in construction time. • The controlled factory environment brings resource optimization, improved quality, precision & finish. • The concrete can be designed industrial by-products such as Fly Ash, Ground granulated blast furnace slag (GGBFS), Micro silica etc. resulting in improved workability & durability, while also conserving natural resources. • Eliminates use of plaster. • Helps in keeping neat & clean construction site and dust free environment. • Optimum use of water through recycling. • Use of shuttering & scaffolding materials is minimal. • All weather construction & better site organization.

- 15. the price of prefabricated construction project is 324.78 yuan/m2, which are 21% higher than that of traditional construction project. The cost difference between refabricated construction and traditional construction mainly comes from precast concrete components. But, Compared with traditional buildings, prefabricated buildings have the advantages of convenient construction, high construction efficiency, high quality of prefabricated components, high safety, as well as saving labor and construction costs. Precast Concrete Construction V/S Conventional Formwork

- 16. Pre-stretched hollow slab Pre-stretched Beam Tilting table for wall panels

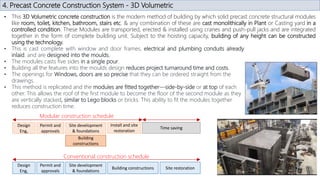

- 18. 4. Precast Concrete Construction System - 3D Volumetric • This 3D Volumetric concrete construction is the modern method of building by which solid precast concrete structural modules like room, toilet, kitchen, bathroom, stairs etc. & any combination of these are cast monolithically in Plant or Casting yard in a controlled condition. These Modules are transported, erected & installed using cranes and push-pull jacks and are integrated together in the form of complete building unit. Subject to the hoisting capacity, building of any height can be constructed using the technology. • This is cast complete with window and door frames, electrical and plumbing conduits already inlaid. and are designed into the moulds. • The modules casts five sides in a single pour. • Building all the features into the moulds design reduces project turnaround time and costs. • The openings for Windows, doors are so precise that they can be ordered straight from the drawings. • This method is replicated and the modules are fitted together—side-by-side or at top of each other. This allows the roof of the first module to become the floor of the second module as they are vertically stacked, similar to Lego blocks or bricks. This ability to fit the modules together reduces construction time. Design Eng, Permit and approvals Site development & foundations Install and site restoration Building constructions Time saving Design Eng, Permit and approvals Site development & foundations Building constructions Site restoration Modular construction schedule Conventional construction schedule

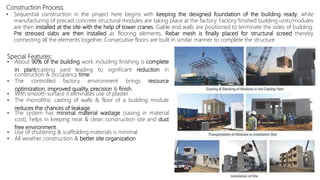

- 19. Special Features: • About 90% of the building work including finishing is complete in plant/casting yard leading to significant reduction in construction & occupancy time. • The controlled factory environment brings resource optimization, improved quality, precision & finish. • With smooth surface it eliminates use of plaster. • The monolithic casting of walls & floor of a building module reduces the chances of leakage. • The system has minimal material wastage (saving in material cost), helps in keeping neat & clean construction site and dust free environment. • Use of shuttering & scaffolding materials is minimal. • All weather construction & better site organization Construction Process: • Sequential construction in the project here begins with keeping the designed foundation of the building ready, while manufacturing of precast concrete structural modules are taking place at the factory. Factory finished building units/modules are then installed at the site with the help of tower cranes. Gable end walls are positioned to terminate the sides of building. Pre stressed slabs are then installed as flooring elements. Rebar mesh is finally placed for structural screed thereby connecting all the elements together. Consecutive floors are built in similar manner to complete the structure

- 22. 5. Light Gauge Steel Structural System & Pre-engineered Steel Structural System (LGSF) • Light Gauge Steel Frame (LGSF) System uses factory made galvanized light gauge steel components. The components/sections are produced by cold forming method and assembled as panels at site forming structural steel framework upto G+3 building. LGSF is used in combination with pre-engineered steel structural system for buildings above G+3 for longevity, speedier construction, strength and resource efficiency. Construction Process: • The sequence of construction comprises of foundation laying, fixing of Pre-Engineered Steel Structural System, fixing of tracks, fixing of wall panels with bracings as required, fixing of floor panels, decking sheet, fixing of electrical & plumbing services and finally fixing of concrete walling panels with light weight concrete as infill. • The other options of dry walling components such as sandwich panels with insulation material in between can also be used. Similarly, the floors can either by composite slab/deck slabs/precast hollow core slabs as per the need & requirements.

- 23. Special Features • High strength to weight ratio. Due to light weight, significant reduction in design earthquake forces is achieved. Making it safer compared to other structures. • Fully integrated computerized system with Centrally Numerical Control (CNC) machine primarily employed for manufacturing of LGSF sections provide very high Precision & accuracy. • Construction being very fast, a typical four storeyed building can be constructed within one month. • Structure being light, does not require heavy foundation • Structural element can be transported to any place including hilly areas to remote places easily making it suitable for far flung regions including difficult terrains. • Structure can be shifted from one location to other without wastage of materials. • Steel used can be recycled multiple times • The system is very useful for post disaster rehabilitation work

- 24. Advantages High Precision :Fully integrated computerised system with CNC machine provides very high accuracy upto 1 mm. Structural: High strength to weight ratio. Earthquake force generation is less due to light weight. Chance of progressive collapse are marginal due to highly ductile and load nature of closely spaced studs/joists. Speed in Construction: Construction speed is very high. A typical four storeyed building can be constructed within one month. Saving in foundation: Structure being light, does not require heavy foundation. Mobility: Structural element can be transported any place including hilly places to remote places easily and structure can be erected fast. Structure can be shifted from one location other without wastage of materials. Environment friendly: Steel used can be recycled when required. • LGSF is 20%-40% quicker build time compared to traditional building methods. • Considerable reduction in production of onsite waste material, and up to 20% reduction in embodied carbon in building fabric. • Due to offsite nature, LGSF is less dependent on 'wet-trade' labour resource.

- 26. 6. PVC Stay In Place Formwork System • The plant manufactured rigid poly-vinyl chloride (PVC) based polymer components serve as a permanent stay-in-place finished form-work for concrete walls. The formwork System being used acts as pre-finished walls requiring no plaster and can be constructed instantly. • This System is suitable for residential and commercial buildings of any height from low rise to high rise. In order to achieve speedier construction, strength and resource efficiency, the composite structure with Pre-Engineered Steel Structural System as structural members is being used in the present project. Construction Process: • At first, the Prefabricated PVC Wall panels and Pre-Engineered Steel Structural Sections as per the design are transported to the Site. • Then, these Sections are erected on the prepared foundation using cranes and required connections. • Floor is installed using decking sheet. Once the structural frame and floor is installed and aligned. • wall panels are fixed on decking floor. The pre-fabricated walling panels having provisions of holes for services conduits, are fixed along with the reinforcement & cavities inside the wall panels are filled with concrete. Upon installment of wall panels, flooring and ceiling, the finishing work is executed.

- 30. Bibliography i. Pre-fabricated sandwich panel system i. https://ghtc-india.gov.in/Content/LHP-Indore.html ii. https://www.epack.in/puf-panels iii. https://balex.eu/en/knowledge-base/news/6-reasons-to-choose-sandwich-panels iv. https://multidecor.in/why-puf-panels-are-the-preferred-choice-for-modular-buildings ii. Monolithic Concrete Construction ( mivan shuttering ) i. https://www.99acres.com/articles/construction-technology-mivan-shuttering-vs-conventional-formwork.html ii. https://www.nobroker.in/blog/mivan-construction-technology-explained/ iii. https://theconstructor.org/building/mivan-formwork-components-procedure-comparision/37256/ iv. https://www.squareyards.com/blog/mivan-technology v. https://ghtc-india.gov.in/Content/LHP-Chennai.html iii. Precast Concrete Construction System – Precast Components Assembled at Site i. https://theconstructor.org/building/methods-precast-concrete-constructions/26523/ ii. https://bmtpc.org/DataFiles/CMS/file/PDF_Files/61_PAC_Urbaanic_Final.pdf iii. https://ghtc-india.gov.in/Content/LHP-Chennai.html iv. Precast Concrete Construction System – 3D Volumetric i. https://ghtc-india.gov.in/Content/LHP-Ranchi.html ii. https://www.nbmcw.com/product-technology/precast/the-3d-monolithic-volumetric-precast.html v. Light Gauge Steel Structural System & Pre-engineered Steel Structural System (LGSF) i. https://bmtpc.org/DataFiles/CMS/file/PDF_Files/TP_08_LGSS_small.pdf ii. https://ghtc-india.gov.in/Content/LHP-Agartala.html iii. https://mgiinfra.com/lgsf.html vi. PVC Stay In Place Formwork System i. https://bmtpc.org/DataFiles/CMS/file/PDF_Files/59_PAC_Novel_PVC_Form.pdf ii. https://ghtc-india.gov.in/Content/LHP-Lucknow.html

- 31. Thank you

![RAPID CONSTRUCTION

TECHNIQUES

Adoption of new technology

For construction practice

BUILDING ENGINEERING AND MANAGEMENT

Construction Management Tool and Technique [MBEM -112]

Deepak Pradhan

1210900048](https://image.slidesharecdn.com/rapidconstructiontechniques-211226081705/85/Rapid-construction-techniques-1-320.jpg)