Prefabrication structure ppt

- 1. PREFABRICATION STRUCTURE Presented by: Abhishek. M Under the Guidance of SRINIVAS K .S Assistant Prof. Dept. of civil Engg, SJBIT

- 2. CONTENTS Introduction Scope Systems Advantage & Disadvantage Literature Review Case Study Conclusion

- 3. INTRODUCTION “Prefabrication is the practice of assembling components of a structure in a factory or other manufacturing site, and transporting complete assemblies to the construction site where the structure is to be located’’.

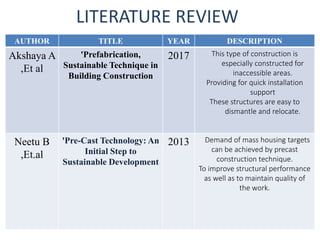

- 4. LITERATURE REVIEW AUTHOR TITLE YEAR DESCRIPTION Akshaya A ,Et al 'Prefabrication, Sustainable Technique in Building Construction 2017 This type of construction is especially constructed for inaccessible areas. Providing for quick installation support These structures are easy to dismantle and relocate. Neetu B ,Et.al 'Pre-Cast Technology: An Initial Step to Sustainable Development 2013 Demand of mass housing targets can be achieved by precast construction technique. To improve structural performance as well as to maintain quality of the work.

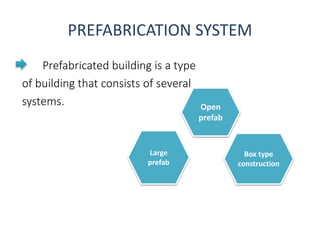

- 5. PREFABRICATION SYSTEM • Prefabricated building is a type of building that consists of several systems. Open prefab Box type construction Large prefab

- 6. PREFABRICATION HOUSE COMPONENTS Panels Capping channel Post Roof Floor system Base channel

- 7. WALL PANELS Precast wall panel is an independently supported vertical member in a prefabricated structure. size of the panels depends on client requirements Wall assembly usually contains insulation, wiring, and pre-cut openings for windows and doors Using an assemblage of metal joints components and anchors. Generally four types of precast panels used Cladding or curtain walls Load-bearing wall units Shear walls Formwork for cast-in-place concrete

- 8. FLOORS • Precast flooring units could be homogeneous or non homogenous. • Homogeneous floors : solid slabs, hollow core slabs. • Non-homogeneous floors : multilayered ones with combinations of light weight concrete

- 9. PREFABRICATION DESIGN GUIDELINES • Material resistance and stability. • Safety in case of fire. • Hygience ,health and environment. • Protection against noise. • Energy saving and heat insulation. These are the parameters which probably might in addition to normal design of the elements

- 10. MATERIAL USED Concrete Steel Treated Wood Aluminium Light weight elements Ceramic product

- 11. MANUFACTURE PROCESS Manufacturing of Prefabrication will be done in two stages 1) Factory Prefabrication. 2)Site Prefabrication. Factory Prefabrication Factory prefabrication is restored in a centrally located plant for manufacture of standardized components on a long form basis. Production of components throughout the year Site Prefabrication. components are manufactured at site near the site of work as possible. The work is normally carried out in open space with locally a valuable labour The equipment machinery and moulds are of mobile nature.

- 12. CASTING Precast components are casted with controlled cement concrete in moulds of required shape and sizes. Vibrator is used to vibrate concrete and this removes any honeycombing inside the components After complete curing is done the components are transported to the site with heavy trucks and erection will be done using cranes with skilled labours TRANSPORTATION Transport of prefab elements inside the factory depends on the method of production selected for the manufacture. Availability of suitable transport equipment, such as tractor ,truck etc, to suits the load and dimension of the member Care should be taken in negotiating sharp beds uneven of slushy roads to avoid undesirable stresses in elements and in transport vehicles. Care should be taken at base packing for supporting the elements.

- 13. ERECTION OR ASSEMBLING Set reference line and determine the position of precast elements to be installed Level pads should be provided for setting the level of the element. Check alignment and verticality of the element For corrugated pipe sleeve or splice sleeve connection, proper and pour non shrink grout into the pipe inlets provided. Keep the installation panels undisturbed for at least 24 hours. Joints casting & sealing. TRANSPORTATION ERECTION

- 14. ADVANTAGES • Provides complex thermal insulation • Improved quality over on-site construction • Saves time where weather conditions allow brief periods of construction • It helps in safety of workers, environmental impact, constructability. DISADVANTAGES • Handling may cause breakage of member. • Difficulty in connecting precast units. • Skilled workmanship is required. • It requires erection equipment.

- 15. CASE STUDY : DREAM VALLEY PROJECT (AMRAPALI GROUP) • 7 buildings of 2B+G+18 floors were completed in 18 months of timeline was made possible through precast technology. • Achieved a slab cycle of 10-12 days for a slab area of 7000 Sqft. • Superior quality & finish of construction. • Cost & time optimisation with the use of hollow-core slabs. • Reduction in concrete & steel factor per Sqft of built-up area. • Elimination of brick work and plaster by the use of precast wall panels & cladding. • Automation & mechanisation of construction project improved overall productivity. • Improved site safety & considerable reduction in wastage, dust & noise on site, thus reduced ecological

- 16. CONCLUSION • Due to the flexibility of the structure in expandability and appearance this prefab houses are the choice. • Less construction time • The prefabrication components and prefab structure eliminate space and time over convectional construction • The use of precast concrete construction can significantly reduce the amount of construction waste generated on construction sites • Reduce adverse environment impact on sites • Enhance quality control of concreting work

- 18. REFERENCE • Abhishek K, Akshaya A '' Prefabrication, Sustainable Technique in Building Construction'' (2017) IJSE Volume 1, Issue 2 • Krish R. Villaitramani, Dhruv P. Hirani ''Prefabricated Construction For Mass Housing In Mumbai'' (2014) (IJIRAE) ISSN: 2349-2163 Volume 1 Issue 9 • Neetu B. Yadav Rushabh A. Shah "Pre-Cast Technology: An Initial Step to Sustainable Development''(2013) | Vol. 1, Issue 7, 2013 | ISSN (online): 2321-0613