Zero carbon Building Design Guidelines V4

- 2. Copyright © Canada Green Building Council (CAGBC), 2024. These materials may be reproduced in whole or in part without charge or wri˜en permission, provided that appropriate source acknowledgements are made and that no changes are made to the contents. All other rights are reserved. The analyses/views in these materials are those of CAGBC, but these analyses/views do not necessarily re°ect those of CAGBC’s a˛liates including supporters, funders, members, and other participants or any endorsement by CAGBC’s a˛liates. These materials are provided on an “as is” basis, and neither CAGBC nor its a˛liates guarantee any parts or aspects of these materials. CAGBC and its a˛liates are not liable (either directly or indirectly) nor accept any legal responsibility for any issues that may be related to relying on the materials (including any consequences from using/applying the materials’ contents). Each user is solely responsible, at the user’s own risk, for any issues arising from any use or application of the materials’ contents. TRADEMARK Zero Carbon Building® is a registered trademark of the Canada Green Building Council (CAGBC). Zero Carbon Building – Design Standard Version 4 ISBN: 978-1-7781454-8-3

- 3. 3 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 01 INTRODUCTION ............................................................................................................................................................................................8 02 OVERVIEW.................................................................................................................................................................................................... 13 2.1 Project Claims and Marketing..........................................................................................................................................................15 2.2 Eligibility ..................................................................................................................................................................................................15 2.2.1 A˜ached Buildings.................................................................................................................................................................15 2.2.2 Additions.................................................................................................................................................................................. 16 2.3 Emissions Covered ............................................................................................................................................................................ 16 2.4 Required Documentation................................................................................................................................................................ 16 2.5 Requirements at a Glance................................................................................................................................................................17 03 ZERO CARBON BALANCE....................................................................................................................................................................... 21 3.1 Embodied Carbon ...............................................................................................................................................................................22 3.1.1 Whole-Building Life Cycle Assessment........................................................................................................................23 3.2 Operational Carbon...........................................................................................................................................................................25 3.2.1 Direct Emissions ....................................................................................................................................................................25 3.2.1.1 Fugitive Emissions from Refrigerants............................................................................................................25 3.2.1.2 Combustion ............................................................................................................................................................26 3.2.1.2.1 Biogas..................................................................................................................................................27 3.2.1.2.2 Biomass.............................................................................................................................................27 3.2.2 Indirect Emissions................................................................................................................................................................28 3.2.2.1 Electricity...............................................................................................................................................................28 3.2.2.2 Owned Renewable Energy Systems.........................................................................................................29 3.2.2.2.1 Onsite.................................................................................................................................................29 3.2.2.2.2 O˝site................................................................................................................................................ 30 3.2.2.3 Green Power Products ................................................................................................................................... 30 3.2.2.4 District Heating and Cooling.........................................................................................................................31 3.2.2.4.1 Green Heat from District Energy Systems...........................................................................31 3.3 Avoided Emissions.............................................................................................................................................................................32 3.3.1 Exported Green Power........................................................................................................................................................32 3.3.2 Carbon O˝sets ......................................................................................................................................................................33 04 LIMITS TO EMISSIONS............................................................................................................................................................................ 35 4.1 Embodied Carbon Limit....................................................................................................................................................................35 4.2 Refrigerant Limit..................................................................................................................................................................................37 4.3 Onsite Combustion Limit for Space Heating ..........................................................................................................................38 4.4 Onsite Combustion Limit for Service Hot Water...................................................................................................................39 4.5 Limits to Other Sources of Combustion................................................................................................................................... 40 05 ALTERNATIVE DESIGN EVALUATION AND TRANSITION PLAN ................................................................................................41 5.1 Evaluation of Alternative Design Without Onsite Combustion..........................................................................................41 5.2 Zero Carbon Transition Plan...........................................................................................................................................................43 5.3 Financial Analysis ...............................................................................................................................................................................45 5.4 Application to District Energy Systems....................................................................................................................................46 TABLE OF CONTENTS

- 4. 4 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 06 ENERGY EFFICIENCY............................................................................................................................................................................... 47 6.1 Flexible Approach.................................................................................................................................................................................51 6.1.1 TEDI Requirements .................................................................................................................................................................51 6.1.2 EUI Requirements..................................................................................................................................................................53 6.1.3 Additional Reporting Requirements..............................................................................................................................54 6.2 Passive Design Approach ...............................................................................................................................................................55 6.2.1 TEDI Requirements...............................................................................................................................................................55 6.2.2 Additional Reporting Requirements.............................................................................................................................55 6.3 Renewable Energy Approach........................................................................................................................................................56 6.3.1 TEDI Requirements ...............................................................................................................................................................56 6.3.2 Zero Carbon Balance Requirements............................................................................................................................56 6.3.3 Additional Reporting Requirements.............................................................................................................................56 07 RESILIENCY TO EXTREME WEATHER................................................................................................................................................. 57 08 AIRTIGHTNESS........................................................................................................................................................................................... 59 09 GRID CITIZENSHIP....................................................................................................................................................................................60 10 IMPACT & INNOVATION........................................................................................................................................................................... 62 11 APPENDIX I – Requirements for Bundled Green Power Products that are not ECOLOGO or Green-e® Certified..64 12 APPENDIX II – Requirements for District Energy Systems..........................................................................................................66 13 APPENDIX III – Summary of v4 Changes........................................................................................................................................... 68 14 APPENDIX IV – Equipment Descriptions........................................................................................................................................... 70 15 GLOSSARY..................................................................................................................................................................................................... 71 16 ACRONYMS.................................................................................................................................................................................................. 76 17 RESOURCES..................................................................................................................................................................................................77 17.1 Embodied Carbon Resources..........................................................................................................................................................77 17.2 Operational Carbon Resources .....................................................................................................................................................78 17.3 Avoided Emissions Resources .......................................................................................................................................................79 17.4 Alternative Design Evaluation and Transition Plan Resources......................................................................................... 80 17.5 Energy E˛ciency Resources .......................................................................................................................................................... 80 17.6 Impact and Innovation Resources.................................................................................................................................................81

- 5. 5 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 LIST OF FIGURES Figure 1 – Estimated cumulative net global anthropogenic CO2 emissions to limit global warming to 1.5 C...................... 8 Figure 2 – Incremental life cycle returns across Canada........................................................................................................................ 10 Figure 3 – Net present value of deep carbon retroÿts for 1970s vintage buildings....................................................................... 11 Figure 4 – Milestones in the sequence of ZCB-Design and ZCB-Performance. ........................................................................... 14 Figure 5 – Calculating the carbon balance....................................................................................................................................................21 Figure 6 – Embodied carbon life cycle stages............................................................................................................................................23 Figure 7 – Global warming potential (GWP) values of common refrigerants. ...............................................................................26 Figure 8 – Climate zones used to determine TEDI targets..................................................................................................................... 50 LIST OF TABLES Table 1 – Emissions covered by ZCB-Design................................................................................................................................................ 16 Table 2 – ZCB-Design and ZCB-Performance requirements compared.......................................................................................... 20 Table 3 – Embodied carbon intensity targets. .............................................................................................................................................35 Table 4 – GWP limits by refrigeration system type....................................................................................................................................37 Table 5 – 100-year GWP of common refrigerants. .....................................................................................................................................37 Table 6 – The three energy e˛ciency approaches...................................................................................................................................47 Table 7 – TEDI pathways for Flexible Approach..........................................................................................................................................51 Table 8 – TEDI targets for Path 2 of Flexible Approach.............................................................................................................................52 Table 9 – EUI pathways for Flexible Approach. ...........................................................................................................................................53 Table 10 – EUI targets for Path 2: Energy Use Intensity. ...........................................................................................................................54 Table 11 – TEDI targets for Passive Design Approach................................................................................................................................55 Table 12 – TEDI targets for Renewable Energy Approach. ......................................................................................................................56

- 6. 6 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 Development Process and Acknowledgements The Zero Carbon Building – Design StandardTM Version 4 (ZCB-Design v4) responds to changes in the Canadian design and construction market since the previous version was launched in 2022. Updates to ZCB-Design were developed using the following guiding principles, established by the Canada Green Building Council’s Zero Carbon Steering Commi˜ee: Revisions to the Standard were informed by two years of market feedback, as well as changing market expectations on operational and embodied carbon emissions. The Zero Carbon Steering Commi˜ee oversaw the changes to ZCB-Design, with the support of the Canada Green Building Council’s Embodied Carbon Technical Advisory Group and the Energy & Engineering Technical Advisory Group. Canada Green Building Council® extends its deepest gratitude to our commi˜ee and working group members. ZERO CARBON BUILDING – DESIGN STANDARD GUIDING PRINCIPLES Prioritize carbon emissions reductions Ensure energy e˛cient design Encourage good grid citizenship Incentivize reductions in embodied carbon Keep it simple and accessible ZERO CARBON STEERING COMMITTEE Wendy Macdonald (Chair), RJC Engineers Ali Hoss, Triovest Douglas Webber (Past-Chair), Purpose Building Ariel Feldman, Choice Properties REIT Christian Cianfrone, OPEN Technologies Elise Woestyn, HCMA Fin MacDonald, Urban Equation Iain MacFadyen, RGS Consultants | ZGF Architects Inc. Jag Singh, Fiera Real Estate Kim Rishel, Hopewell Development Lisa Westerho˝, Introba Marc-Antoine Chenail, BPA Ma˜ Cable, Enbridge Gas Michael Pires, WSP Canada Patrick Armstrong, Modern Niagara Peter Whitred, Canada Post Rob Cooney, Treasury Board Secretariat Samantha Lane, Entuitive Stephen Montgomery, PCL Taylor Graf, Public Services and Procurement Canada

- 7. 7 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 EMBODIED CARBON TECHNICAL ADVISORY GROUP ENERGY & ENGINEERING TECHNICAL ADVISORY GROUP Guillaume Martel (Chair), Provencher Roy Anik Bastien Thouin, Société québécoise des infrastructures Ben Amor, National Research Council Canada Caroline Butchart, Aspect Engineers Chantal Lavigne, Vertima Iain MacFadyen, ZGF Architects | RGS Consultants Jeremy Field, Introba Kalum Galle, Morrison Hershÿeld Kathleen Tiede, Crosier Kilgour Leland Dadson, MJMA Architecture and Design Michael Hiebert, Number TEN Architectural Group Michelle Christopherson, WSP Navisa Jain, EllisDon Ryley Picken, Treasury Board Secretariat Ryan Zizzo, Mantle Developments Stephanie Fargas, DIALOG Yury Kulikov, Fast + Epp Zachary Zandona, City of Toronto Zahra Teshnizi, City of Vancouver Alex Blue (Chair), Evoke Buildings Andrej Simjanov, Remedy Engineering Andrew Morrison, Caneta Research Inc. Craig McIntyre, EQ Building Performance Inc. Curt Hepting, Enersys Analytics Ltd. Geneviève Lachance, Société québécoise des infrastructures Ian McRobie, H.H. Angus Ivan Tang, Inform Energy Solutions James Bererton, Stantec Kevin Henry, HDR Lori Hipwell, Pure Industrial Mark Terpstra, Alberta Infrastructure Martin Roy, Martin Roy et Associés Mike Hassaballa, H.H. Angus Steve Kemp, RDH Building Science Inc. Wendy Macdonald, RJC Engineers Yichao Chen, Cadillac Fairview

- 8. 8 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 01 INTRODUCTION To avoid the worst impacts of climate change, all nations must focus their efforts on carbon reduction. In Canada, building construction and operations must e˝ectively eliminate greenhouse gas (GHG) emissions to meet the national target of carbon neutrality by 2050. To achieve this goal, each new building design must target zero carbon emissions to avoid costly retroÿts down the line. There is no time to wait. The Intergovernmental Panel on Climate Change (IPCC) has ÿxed the world’s remaining carbon budget – the maximum amount of carbon dioxide (CO2 ) that can be released into the atmosphere – at 500 gigatonnes (Gt) of CO2 .1 This budget has been set to keep global warming to 1.5 C with a 50 percent likelihood. However, based on data from 2019 emissions, at the world’s rate of 40 Gt of total GHG emissions per year, our remaining carbon budget will be depleted in less than eight years, risking a global temperature increase that will signiÿcantly alter our climate. Figure 1 – Estimated cumulative net global anthropogenic CO2 emissions to limit global warming to 1.5 C. 1 IPCC. (2021). Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change. 200 100 400 300 500 0 Cumulative Carbon Emissions (Gt CO₂e) 2024 2025 2026 2027 2028 2029 2030 2031 2032 2033 2034 600 700 2035 Remaining carbon budget for 1.5 C temperature rise 40 Gt CO / year 01 INTRODUCTION < Back to TOC Go to 02 OVERVIEW >

- 9. 9 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 01 INTRODUCTION Staying within the remaining carbon budget and mitigating the e˝ects of climate change requires collective action from across the building sector. Every year that passes without signiÿcantly reducing GHG emissions erodes the global carbon budget, shortening what li˜le time we have leˆ to reach zero carbon and remain within our planetary boundaries.2 Fortunately, the building sector is well-positioned to support Canada’s decarbonization e˝orts. Building operations are responsible for 17 percent of Canada’s carbon emissions,3 with construction and materials representing an estimated 10 percent more.4 The transition to zero- carbon buildings will generate new and innovative design strategies, expanding opportunities for industry growth and job creation. The Canada Green Building Council® (CAGBC) launched the Zero Carbon Building Standards™ (ZCB Standards) in 2017 to assist the industry’s transition to zero carbon. Every day, projects pursuing certiÿcation under the ZCB Standards are pushing the boundaries and demonstrating that there is a zero-carbon future for all buildings. Certifying under the ZCB Standards mean taking responsibility for all carbon emissions over a building’s life cycle. It is an ambitious but nonetheless critical objective, because within the context of a global carbon budget, every kilogram of carbon counts. Published in 2019, CAGBC’s Making the Case for Building to Zero Carbon report conÿrmed that zero-carbon buildings are both technically feasible and ÿnancially viable.5 On average, zero-carbon buildings can provide a positive ÿnancial return over a 25-year life cycle when considering national carbon pollution pricing. They also require only a modest capital cost premium. The ÿnancial returns for zero carbon buildings will only increase as the cost of carbon rises, while they also help mitigate future costs from utilities, regulations, retroÿts and extreme weather. 2 Rockström et al. (2009). Planetary Boundaries: Exploring the Safe Operating Space for Humanity. 3 Environment and Climate Change Canada. (2016). Pan-Canadian Framework on Clean Growth and Climate Change. Canada’s Plan to Address Climate Change and Grow the Economy. 4 Global Alliance for Buildings and Construction. (2024). Global Status Report for Buildings and Construction. 5 Canada Green Building Council. (2019). Making the Case for Building to Zero Carbon. < Back to 01 INTRODUCTION Go to 02 OVERVIEW >

- 10. 10 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 01 INTRODUCTION INCREMENTAL LIFE CYCLE RETURNS ACROSS CANADA CALGARY 1% $32/m2 $18/tCO2 e TORONTO 1% $58/m2 $110/tCO2 e OTTAWA 1% $51/m2 $79/tCO2 e MONTREAL 0% -$4/m2 -$6/tCO2 e HALIFAX 4% $187/m2 $122/tCO2 e VANCOUVER -1% -$55/m2 -$137/tCO2 e Figure 2 – Incremental life cycle returns across Canada.6 In 2021, CAGBC released the Decarbonizing Canada’s Large Buildings report, which studied the costs of deep carbon retroÿts for 1970s and 1990s vintage buildings, identifying key market barriers and solutions. The archetypes within the study can reduce fossil fuel consumption by at least 93 percent, while slashing energy usage by more than 70 percent. Many of the archetypes also yielded a positive ÿnancial return on a deep carbon retroÿt using a 40-year life cycle, with the remainder becoming cost viable as carbon and energy prices increase. 6 Ibid. < Back to 01 INTRODUCTION Go to 02 OVERVIEW >

- 11. 11 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 01 INTRODUCTION Figure 3 – Net present value of deep carbon retrofits for 1970s vintage buildings.7 In 2019, the World Green Building Council called for a 40 percent reduction in embodied carbon8 by 2030.9 While Canada’s building sector has made strides in designing buildings that operate without operational carbon emissions, addressing embodied carbon remains a signiÿcant challenge. In 2021, CABGC released a white paper titled Embodied Carbon: A Primer for Buildings in Canada to equip the building sector with essential information to understand and tackle embodied carbon in both new and existing buildings. The paper posits that between 2022 and 2050, embodied carbon could account for over 90 percent of emissions from new buildings. This is a signiÿcant source of emissions that demands a˜ention during the design stage of any project. Lastly, provinces and territories are embarking on a large-scale energy transition to accommodate Canada’s national strategy for a low-carbon future. Buildings can and must do their part to support the transition. CAGBC envisions buildings as “good grid citizens” that ensure energy e˛ciency, generate renewable energy onsite, and take steps to reduce and manage peak electrical demand, which may include energy storage and active participation in demand response programs. 7 Canada Green Building Council (2021). Decarbonizing Canada’s Large Buildings. 8 To assist readers, key terms are bolded and defined in the Glossary. 9 World Green Building Council. (2019). Bringing Embodied Carbon Upfront: Coordinated action for the building and construction sector to tackle embodied carbon. Halifax Montreal Toronto NPV Positive with Positive IRR NPV Negative with Positive IRR NPV Negative with Negative IRR Edmonton Vancouver 1000 900 800 700 600 500 400 300 200 100 0 -100 -200 -300 -400 -500 -600 -700 Low-rise Office Low-rise MURB Mid-rise Office Net Present Value ($/m) Mid-rise MURB Primary School Low-rise Office Low-rise MURB Mid-rise Office Mid-rise MURB Primary School Low-rise Office Low-rise MURB Mid-rise Office Mid-rise MURB Primary School Low-rise Office Low-rise MURB Mid-rise Office Mid-rise MURB Primary School Low-rise Office Low-rise MURB Mid-rise Office Mid-rise MURB Primary School < Back to 01 INTRODUCTION Go to 02 OVERVIEW >

- 12. 12 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 01 INTRODUCTION THE PROCESS OF DESIGNING FOR ZERO CARBON INTEGRATED DESIGN The application of an integrated design process is the ÿrst step towards ensuring the success of any project targeting zero carbon. Bring a broad, interdisciplinary team together as early as possible and collaborate throughout the course of the new building or deep retroÿt project to ÿnd the best, lowest- cost approach to zero carbon. LIMITING COMBUSTION Eliminating onsite combustion is the top priority when designing for zero carbon. A well-designed electric building will have lower carbon emissions in almost all regions of Canada today, and ongoing e˝orts to reduce the carbon intensity of electrical grids will ensure that the emissions of combustion-free buildings continue to decline. MINIMIZING THERMAL ENERGY DEMAND AND EMBODIED CARBON Project teams must balance the dual goals of minimizing embodied carbon and reducing energy demand – particularly the heating and cooling loads. Improvements to the building’s envelope are critical to lower thermal energy demand, enable heating solutions that avoid combustion, and minimize peak demand on the electricity grid. However, envelope improvements can increase embodied carbon, and in many regions of Canada, the embodied carbon of e˛cient, all-electric buildings already outweighs the cumulative operating emissions over the life of the building. Teams must also consider costs, comfort, passive survivability, and other criteria. ENERGY EFFICIENCY Meeting a building’s energy needs e˛ciently is a critical next step to reduce energy use and save on energy costs. From ventilation, heating and cooling to hot water and lighting, e˛ciency focuses on meeting energy needs with the least energy and carbon emissions. GREEN POWER AND ENERGY STORAGE Next, consider how a building might generate onsite renewable energy, accounting for grid interactions to ensure real carbon reductions. Energy storage, whether electrical or thermal, is a recognized strategy to help minimize grid impacts, reduce or eliminate the need for fossil fuels to meet peak heating demand, and increase building resilience. Procuring green power generated o˝site can also contribute to mitigating emissions. CARBON OFFSETS The residual emissions from embodied carbon, energy use and refrigerant leaks can be mitigated through the purchase of carbon o˝sets as a ÿnal measure towards a˜aining zero carbon. 01 INTRODUCTION < Back to 01 INTRODUCTION Go to 02 OVERVIEW >

- 13. 13 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 02 OVERVIEW The Zero Carbon Building – Design (ZCB-Design) Standard™ is a made-in- Canada framework that guides the design of low-carbon, highly efficient buildings and sets a strong foundation for achieving zero-carbon operations once the building commences occupancy. It applies to new construction and major renovations. The Standard recognizes that many strategies exist for reducing whole-life carbon emissions at the design and operating stages and provides enough °exibility for eligible buildings of all types and sizes to achieve certiÿcation. ZCB-Design evaluates energy e˛ciency and carbon emissions across the building life cycle based on the project’s ÿnal design. Even the best building design cannot ensure zero carbon operations, thus the Canada Green Building Council® (CAGBC) Zero Carbon Building – Performance (ZCB-Performance) Standard™ can be used to verify the building’s impact on the climate annually. ZCB-Performance relies on operating data over the course of one year of operation, including purchases of energy and carbon o°sets. 02 OVERVIEW < Back to TOC Go to 2.1 PROJECT CLAIMS AND MARKETING > Thunder Bay Art Gallery Waterfront, Thunder Bay, Ontario, ZCB-Design v2.

- 14. 14 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 02 OVERVIEW Figure 4 – Milestones in the sequence of ZCB-Design and ZCB-Performance. DESIGN 1 ZCB-Design Registration CONSTRUCTION 2 ZCB-Design Submission and Certiÿcation OPERATION 3 ZCB-Performance Annual Submission and Certiÿcation The ZCB-Design and ZCB-Performance Standards work in tandem as illustrated below. YEAR 1 YEAR 2 YEAR 3 YEAR 4 YEAR 5 1. Registration indicates the intent to pursue certiÿcation to ZCB-Design and conÿrms the version of the Standard to be used. 2. Teams can submit for certiÿcation once the construction documents are completed. CAGBC reviews the materials provided, clariÿes outstanding issues, and awards certiÿcations if the requirements have been met. Certiÿcation is awarded based on the project’s ÿnal design. 3. Projects are eligible to submit for ZCB-Performance certiÿcation aˆer 12 months of operations if they have achieved ZCB-Design. The ÿrst ZCB-Performance certiÿcation includes veriÿcation of airtightness. The embodied carbon of the structural and envelope materials must also be o˝set, either in the ÿrst ZCB-Performance certiÿcation or in equal amounts annually over as many as ÿve years. Projects that have not achieved ZCB-Design are eligible to submit for ZCB-Performance aˆer three years of operations. < Back to 02 OVERVIEW Go to 2.1 PROJECT CLAIMS AND MARKETING >

- 15. 15 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 2.1 PROJECT CLAIMS AND MARKETING 2.1 PROJECT CLAIMS AND MARKETING ZCB-Design certiÿed projects are not permi˜ed to display a certiÿcation mark (logo and year) on the building or make a claim of zero carbon operations. Communications about the achievement of ZCB-Design certiÿcation should instead re°ect the expectation that operations will be veriÿed through certiÿcation under the ZCB-Performance Standard following building occupancy. More information on how to market ZCB-Design certiÿed projects can be found on cagbc.org. ZCB-Design certiÿcation may not be used to make a carbon-neutral claim about a product or service originating from a ZCB-Design certiÿed building; however, it may form part of a strategy to achieve a carbon neutral claim. 2.2 ELIGIBILITY The ZCB-Design Standard applies to new buildings and major renovations to existing buildings, provided they include HVAC, envelope, and/or interior renovations that require a new certiÿcate of occupancy and/or prevent normal building operations from occurring while they are in process. Proposed changes of use to the building are also considered major renovations. ZCB-Design applies to all buildings except single and multi-family residential buildings that fall under Part 9 of the National Building Code. That is, the Standard applies to all buildings except residential buildings that are three storeys or less, and smaller than 600 m2 . ZCB-Design was created to evaluate entire individual buildings but may also be applied to a˜ached buildings and additions, per Sections 2.2.1 and 2.2.2. Multiple buildings that share a common site cannot be certiÿed under a single project unless a˜ached by programmable space. Buildings that have no physical connection or are connected only by corridors, parking, mechanical rooms, or storage rooms are considered separate buildings. 2.2.1 ATTACHED BUILDINGS A building that is a˜ached to another building may independently pursue ZCB-Design certiÿcation. The following rules apply: 1. An a˜ached building must be physically distinct to be considered separately for certiÿcation. 2. The a˜ached building must have a distinct identity. This ensures that the certiÿcation is communicated appropriately to the building users and the public. 3. A˜ached buildings generally share a common site and will need to consider appropriate separation of that site to determine the emission sources to include in the project. 4. An a˜ached building must have a separate ventilation system and energy meters capable of measuring energy use for electricity, heating, and cooling. This is necessary to demonstrate compliance with the energy and carbon requirements of the Standard. 5. Applicants must seek clariÿcation with CAGBC by emailing zerocarbon@cagbc.org if they are uncertain about a˜ached building compliance. < Back to 02 OVERVIEW Go to 2.3 EMISSIONS COVERED >

- 16. 16 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 2.3 EMISSIONS COVERED 2.2.2 ADDITIONS New building additions may pursue ZCB-Design certiÿcation. The following rules apply: 1. Additions must be physically distinct, representing a newly constructed, unique area of a building. The distinct space must also be re°ected in the project name when registering. 2. Additions must have separate ventilation systems as well as energy meters capable of measuring energy use for electricity, heating, and cooling. This is necessary to demonstrate compliance with the energy and carbon requirements of the Standard. 2.3 EMISSIONS COVERED The ZCB-Design Standard applies to the entirety of the building site and includes all emissions outlined below. For the purpose of classifying emissions, all building energy use is assumed to be under the control of the building owner. 2.4 REQUIRED DOCUMENTATION Applicants must complete the ZCB-Design v4 Workbook™ to demonstrate compliance with ZCB-Design requirements. The workbook contains a full list of required supporting documentation. Applicants should use the most recent version of the ZCB-Design v4 Workbook™ ; however, they may opt to use the version available at the time of project registration, provided that the emission factors from the most recent version are applied. EMISSIONS CATEGORY CLASSIFICATION Emissions from the combustion of fuels onsite, including tenant equipment Direct, Scope 1 Fugitive emissions from the leakage of refrigerants from base building HVAC systems, service hot water systems, and commercial refrigeration equipment, including tenant equipment Direct, Scope 1 Emissions from purchased electricity, heating, and cooling, including tenant equipment Indirect, Scope 2 Embodied carbon emissions that are associated with new structural and building envelope materials Indirect, Scope 3 Table 1 – Emissions covered by ZCB-Design. < Back to 2.1 PROJECT CLAIMS AND MARKETING Go to 2.5 REQUIREMENTS AT A GLANCE >

- 17. 17 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 2.5 REQUIREMENTS AT A GLANCE Please refer to the ZCB Certification Guide for instructions on submi˜ing the required documentation, as well as information regarding the certiÿcation process. The ZCB-Design v4 Energy Modelling Guidelines™ is also an important resource that must be followed. The guidelines contain requirements speciÿc to the development of the energy model required for ZCB-Design certiÿcation, as well as additional guidance that projects must follow. 2.5 REQUIREMENTS AT A GLANCE Revisions to the ZCB-Design Standard were informed by two years of market feedback, as well as changing market expectations and capabilities related to operational and embodied carbon emissions. The requirements for the ZCB-Design v4 Standard were developed using the following guiding principles established by the Zero Carbon Steering Commi˜ee: ZERO CARBON BUILDING – DESIGN STANDARD GUIDING PRINCIPLES Prioritize carbon emissions reductions Ensure energy e˛cient design Encourage good grid citizenship Incentivize reductions in embodied carbon Keep it simple and accessible < Back to 2.1 PROJECT CLAIMS AND MARKETING Go to 03 ZERO CARBON BALANCE >

- 18. 18 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 2.5 REQUIREMENTS AT A GLANCE A high-level summary of the ZCB-Design v4 Standard’s requirements is presented below. A summary of changes from the previous version can be found in Appendix III. ZERO CARBON BALANCE Model a carbon balance of zero or be˜er based on the net sources and sinks of embodied, operational, and avoided emissions. Green power products (e.g. renewable energy certiÿcates) and carbon o°sets are permi˜ed as part of the carbon balance but do not need to be purchased at the time of ZCB-Design certiÿcation. LIMITS TO EMISSIONS • Demonstrate that the embodied carbon intensity is at or below the established target or meets the percentage reduction target compared to a baseline building. • Demonstrate that all space heating is designed to be provided using non- combustion-based technologies down to an outdoor air temperature of -15 C or the design temperature, whichever is higher. • Demonstrate that all service hot water is designed to be provided without using onsite combustion-based technologies. Multi-unit residential buildings, long-term care facilities, and other occupancy types with signiÿcant hot water demand may adopt a hybrid water heating approach where service hot water is heated to at least 45 C without combustion; further heating to reach the set-point may use combustion. Alternatively, at least 70 percent of the total annual load must be provided without combustion. • Demonstrate that refrigerants used in all HVAC equipment, service hot water systems, and commercial refrigeration equipment comply with global warming potential (GWP) limits. • Combustion-based ÿreplaces, as well as gas stoves and ranges in residential suites, are not permi˜ed. ALTERNATIVE DESIGN AND TRANSITION PLAN Projects that use any combustion for space heating or service hot water must evaluate an alternative design that does not use these forms of combustion and prepare a Zero Carbon Transition Plan. ENERGY EFFICIENCY • Report the modelled thermal energy demand intensity (TEDI) and energy use intensity (EUI). • Meet the energy performance requirements of the selected approach to energy e˛ciency. 2.5 REQUIREMENTS AT A GLANCE < Back to 2.5 REQUIREMENTS AT A GLANCE Go to 03 ZERO CARBON BALANCE >

- 19. 19 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 2.5 REQUIREMENTS AT A GLANCE When pursuing ZCB-Performance certiÿcation, projects certiÿed under ZCB-Design v2 and later versions must meet the additional requirements below; compliance will be reviewed during the ÿrst annual ZCB-Performance review. 1. O˝set the embodied carbon reported for ZCB-Design certiÿcation. 2. Perform airtightness testing prior to occupancy. RESILIENCY TO FUTURE WEATHER Applicants are encouraged to submit the results of any design condition or energy model sensitivity analysis performed using future weather data. AIRTIGHTNESS Justify the use of a lower modelled air leakage rate, if applicable. GRID CITIZENSHIP • Report the summer and winter peak electrical demand. • Projects with any onsite renewable energy, energy storage, or demand response capabilities that reduce peak electrical load should report the reduction as a percentage. IMPACT AND INNOVATION Demonstrate the inclusion of two Impact and Innovation strategies. At least one of these strategies must come from the pre-approved list. 2.5 REQUIREMENTS AT A GLANCE < Back to 2.5 REQUIREMENTS AT A GLANCE Go to 03 ZERO CARBON BALANCE >

- 20. 20 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 2.5 REQUIREMENTS AT A GLANCE ZCB-DESIGN v4 One-time certiÿcation for new buildings and major renovations ZCB-PERFORMANCE v2 Annual certiÿcation for existing buildings ZERO CARBON BALANCE Model a zero carbon balance; purchase of green power products or o˝sets not required Achieve zero carbon balance with purchase of green power products or o˝sets if needed LIMITS TO EMISSIONS Meet limits for embodied carbon, space heating, service hot water, refrigerants, ÿreplaces, stoves, and ranges O˝set emissions ALTERNATIVE DESIGN AND TRANSITION PLAN If required, evaluate alternative design and develop Transition Plan Update Transition Plan every 5 years ENERGY EFFICIENCY Meet one of three approaches Report EUI RESILIENCY Report ÿndings from an optional future-weather sensitivity analysis No requirement AIRTIGHTNESS Justify if an air leakage rate lower than the default is used Conduct testing if ZCB-Design v2, v3, or v4 certiÿed GRID CITIZENSHIP Report seasonal peaks and any electrical load reductions Report seasonal peaks IMPACT AND INNOVATION Apply two strategies No requirement Table 2 – ZCB-Design and ZCB-Performance requirements compared. A summary and comparison of ZCB-Design and ZCB-Performance requirements is provided in Table 2. < Back to 2.5 REQUIREMENTS AT A GLANCE Go to 03 ZERO CARBON BALANCE >

- 21. 21 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 03 ZERO CARBON BALANCE < Back to TOC Go to 3.1 EMBODIED CARBON > 03 ZERO CARBON BALANCE This section of the Standard explains the carbon accounting used to demonstrate a carbon balance of zero or be˜er. A carbon balance of zero or better is the ultimate goal of decarbonization efforts. The carbon balance reaches zero when the sources and sinks of carbon emissions in a building are balanced over a 60-year lifespan. A carbon balance of zero or be˜er must be demonstrated for Zero Carbon Building – Design (ZCB-Design) Standard™ certiÿcation. ZCB-Design recognizes that the holistic assessment of carbon emissions is the best measure of progress toward minimizing climate change impacts from buildings. Applicants must quantify, reduce, and optimize emissions across the building’s life cycle, recognizing the impact of construction materials and building operations, as illustrated in Figure 5. Embodied carbon, operational carbon, and avoided carbon emissions are separately addressed in Sections 3.1, 3.2, and 3.3. Together, embodied carbon and operational carbon over the life of the building are known as whole-life carbon. The ZCB-Design v4 Workbook™ has been designed to simplify the calculation of the carbon balance, and applicants must use this tool to demonstrate the zero carbon balance has been achieved. OPERATIONAL CARBON • Direct emissions • Indirect emissions EMBODIED CARBON • Upfront carbon • Use stage embodied carbon • End of life carbon + - AVOIDED EMISSIONS • Exported green power • Carbon o˝sets = NET EMISSIONS Figure 5 – Calculating the carbon balance.

- 22. 22 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 3.1 EMBODIED CARBON < Back to 03 ZERO CARBON BALANCE Go to 3.2 OPERATIONAL CARBON > 3.1 EMBODIED CARBON Embodied carbon emissions are derived from the manufacturing, transport, installation, use, and end-of-life of building materials. In many regions of Canada, an e˛cient, all- electric building’s embodied carbon will outweigh its cumulative operating emissions over its entire lifespan.10 Globally, embodied carbon emissions represent approximately 10 percent of all energy-related carbon emissions.11 Furthermore, emissions occurring during the production and construction phases of a building, a subset of embodied carbon referred to as upfront carbon, are released into the atmosphere before the building is even operational; given that the timeframe for meaningful climate action is shrinking, there is a growing awareness of the critical importance of addressing this upfront carbon. The ZCB-Design Standard focuses on carbon emissions across the entire life cycle of the building. As such, reductions in embodied carbon should be pursued as part of an approach that includes consideration of carbon from building operations (‘operational carbon’). Decisions about embodied carbon may impact operational carbon and vice versa. To assess embodied carbon’s contribution to the carbon balance of the project, a whole- building life cycle assessment (wbLCA) must be done in conformity with Section 3.1.1 Whole- Building Life Cycle Assessment. Projects must also report their embodied carbon intensity or the total embodied carbon divided by the built °oor area. It should be noted that built ˝oor area includes the °oor area of underground spaces including parking but excludes balconies and terraces.12 10 Derived from: Canada Green Building Council. (2021). Embodied Carbon: A Primer for Buildings in Canada. 11 Global Alliance for Buildings and Construction. (2024). Global Status Report for Buildings and Construction, p. 29. This figure may be conservative as it only includes concrete, steel, aluminum, brick, and glass. It also only accounts for manufacturing and does not include other life cycle stages (construction, use, and end of life). 12 For guidance on calculation of embodied carbon intensity see the National Research Council’s 2024 National Whole-building Life Cycle Assessment Practitioner’s Guide: Guidance for Compliance Reporting of Embodied Carbon in Canadian Building Construction. Embodied carbon can signiÿcantly outweigh operational carbon, and most of it is emi˜ed before a building is even operational.

- 23. 23 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 3.1 EMBODIED CARBON < Back to 03 ZERO CARBON BALANCE Go to 3.2 OPERATIONAL CARBON > Projects that have certiÿed under ZCB-Design will be required to o˝set their embodied carbon to achieve ZCB-Performance certiÿcation. Aˆer minimizing embodied carbon emissions during design and construction, projects that have achieved ZCB-Design must o˝set their embodied carbon to achieve Zero Carbon Building – Performance (ZCB-Performance) Standard™ certiÿcation. Projects that intend to seek ZCB-Performance certiÿcation may wish to o˝set their embodied carbon using the capital budget for design and construction. While this approach is encouraged, ZCB- Performance provides the °exibility to mitigate embodied carbon by o˝se˜ing equal amounts annually over as many as ÿve years. Beyond the life cycle carbon (life cycle stage D) is not included in embodied carbon and does not need to be o˝set when seeking ZCB- Performance certiÿcation. 3.1.1 WHOLE-BUILDING LIFE CYCLE ASSESSMENT Projects must conduct a whole-building life cycle assessment (wbLCA) of the building materials that includes the following life cycle stages, as illustrated in Figure 6: • Upfront carbon (life cycle stages A1-5) • Use stage embodied carbon (life cycle stages B1-5) • End of life carbon (life cycle stages C1-4) Figure 6 – Embodied carbon life cycle stages. WHOLE-LIFE CARBON EMBODIED CARBON UPFRONT CARBON OPERATIONAL CARBON OUT OF SCOPE BEYOND THE LIFE CYCLE USE STAGE EMBODIED CARBON END OF LIFE CARBON Raw material supply Transport Manufacturing PRODUCT stage A1-3 A1 A2 A3 Construction-installation process Transport CONSTRUCTION PROCESS stage A4 A5 A4-5 Operational energy use B6 Operational water use B7 B1 B2 B3 B4 B5 Use Maintenance Repair Replacement Refurbishment B1-7 USE stage Transport Waste processing Disposal De-construction / Demolition C1 C2 C3 C4 C1-4 END OF LIFE stage D Beneÿts and loads beyond the building life cycle Supplementary information beyond the building life cycle Reuse Recovery Recycle

- 24. 24 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 3.1 EMBODIED CARBON < Back to 03 ZERO CARBON BALANCE Go to 3.2 OPERATIONAL CARBON > The wbLCA must be conducted using the methodology from the National Research Council (NRC) – National Whole-Building Life Cycle Assessment Practitioner’s Guide: Guidance for Compliance Reporting of Embodied Carbon in Canadian Building Construction (hereaˆer referred to as the National wbLCA Practitioner’s Guide). This document provides practical guidance on how to assess and demonstrate reductions in the estimated embodied carbon of new construction and renovation designs. It is meant to complement and be used in conjunction with the National Guidelines for Whole-Building Life Cycle Assessment. The National wbLCA Practitioner’s Guide was created to enable greater consistency in the methodologies, boundaries, and assumptions used in wbLCAs for Part 3 buildings that intend to demonstrate compliance with certiÿcation programs and jurisdictional requirements. Using a common Canadian methodology, it streamlines the work for practitioners and begins to allow for program comparisons. Projects must adhere to the following direction when applying the National wbLCA Practitioner’s Guide. Where there are di˝erences between the guide and the ZCB-Design Standard, the la˜er takes precedence. Projects must: 1. Follow the Cradle-to-Grave Embodied Carbon Assessments approach outlined in the guide, addressing life cycle stages A1-A5, B1-5, and C1-C4. The guide provides direction on handling stages for which information is not available. As noted in the guide, life cycle stage D shall not be included in the embodied carbon calculations used for compliance but may be calculated and reported separately. 2. Follow the required scope elements for structure and enclosure, speciÿcally substructure (foundations, subgrade enclosures, slab-on-grades) and shell (superstructure, exterior vertical enclosures, exterior horizontal enclosures). Currently, ZCB-Design v4 does not include those elements identiÿed as ‘optional scope’ (e.g., interiors, sitework, and mechanical, electrical, and plumbing systems) in assessing embodied carbon’s contribution to the project’s carbon balance. 3. Conduct a wbLCA for each building. Where buildings a˜ach through an underground parking garage, each building must pursue certiÿcation independently, as noted in Section 2.2 Eligibility. Project teams must separate the embodied carbon assessment for the underground space and appropriately a˜ribute it to the buildings aboveground based on their °oor areas or another suitable methodology. While the National wbLCA Practitioner’s Guide allows for wbLCA assessments to be completed on multiple buildings joined only by underground parking, ZCB-Design v4 does not. The embodied carbon assessment must re°ect the Construction Documents Stage, as noted in the National wbLCA Practitioner’s Guide; an Early Design Stage assessment cannot be used for certiÿcation. Note, it is recommended that discussions on embodied carbon begin during pre-design, and that analysis begin no later than schematic design to in°uence project outcomes.

- 25. 25 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 3.2 OPERATIONAL CARBON < Back to 3.1 EMBODIED CARBON Go to 3.3 AVOIDED EMISSIONS > 3.2 OPERATIONAL CARBON Operational carbon emissions are associated with energy use and potential releases of refrigerants during regular building operations. When targeting ZCB-Design certiÿcation, reducing fossil fuel consumption and the resulting operational carbon, is the priority. Once occupied, operational carbon becomes the critical measure of annual carbon emissions. To achieve ZCB-Performance certiÿcation, operational carbon must be compensated for with avoided emissions (carbon o°sets and exported green power) to demonstrate that a building has minimized its climatic impact during the performance period. Operational carbon must be assessed and reported in the ZCB-Design v4 Workbook™ , following the details below. While this section details how projects account for operational carbon in the carbon balance, Section 4.0 Limits to Emissions speciÿes the maximum limits for several sources of operational carbon. 3.2.1 DIRECT EMISSIONS Direct emissions refer to emissions that occur at the project site because of the combustion of fuels or the release of refrigerants. 3.2.1.1 FUGITIVE EMISSIONS FROM REFRIGERANTS Low-carbon designs oˆen take advantage of e˛cient heat pump technology. Refrigerants used in heat pump equipment can contribute to climate change if they leak into the atmosphere or are improperly disposed of. Project teams should consider the global warming potential (GWP) of refrigerant options when making design decisions, as the heat-trapping potential of some can be hundreds or even thousands of times greater than other choices. ZCB-Design certiÿcation requires projects to report the total quantity, type, and GWP of each refrigerant contained in all base building HVAC systems, service hot water systems, and commercial refrigeration equipment. The total global warming impact of the refrigerants will be assessed in the ZCB-Design v4 Workbook™ , enabling project teams to understand how refrigerants impact the carbon balance. The Workbook includes GWP values for common refrigerants, referencing the IPCC 5th Assessment Report as shown in Table 5 of Section 4.2 Refrigerant Limit. In calculating the carbon balance, the ZCB-Design v4 Workbook™ also incorporates assumptions for annual average refrigerant leakage. The ZCB-Performance Standard requires that any fugitive refrigerant emissions be o˝set. The ZCB-Design Standard leverages the GHG Protocol’s Corporate Accounting and Reporting Standard methodology for quantifying emissions from building operations.

- 26. 26 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 3.2 OPERATIONAL CARBON < Back to 3.1 EMBODIED CARBON Go to 3.3 AVOIDED EMISSIONS > Careful selection of mechanical systems and establishing commissioning and preventative- maintenance plans can reduce the amount of carbon o°sets needed in the future. Consistent with the approach taken by Canada’s National Inventory Report, emissions in the ZCB-Design Standard are presented in carbon dioxide equivalents (CO2 e), or the volume of CO2 emissions that would have an equivalent GWP over 100 years. However, projects are encouraged to also consider emissions using 20-year GWP values. Some types of refrigerants act as near-term climate forcers, which means they have a short life but a high heat-trapping potential. For example, HFC-32 has 2,330 times the heat-trapping potential of CO2 when measured over 20 years, but only 677 times the heat-trapping potential of CO2 over 100 years, as shown in Figure 7.13 Using 100-year GWP values misrepresents the large heat-trapping impact of these emissions over the next few decades – the period of time that we have leˆ to take meaningful action on climate change.14 REFRIGERANT GLOBAL WARMING POTENTIAL 3.2.1.2 COMBUSTION The ZCB-Design v4 Workbook™ applies emissions factors to calculate annual building emissions associated with onsite combustion. Provincial GHG factors are used for natural gas, while national factors are used for other fossil fuels (e.g., propane, fuel oil, and diesel). Emission factors are sourced from the most recent release of Canada’s National Inventory Report and may be updated periodically. Projects must use the emissions factors in the most recent ZCB- Design v4 Workbook™ available at the time of submission for certiÿcation. 13 IPCC. (2013). Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Values are derived from Table 8.A.1. 14 Chartered Professional Accountants Canada, The Time Value of Carbon – Smart Strategies to Accelerate Emissions Reductions, p.11. Figure 7 – Global warming potential (GWP) values of common refrigerants. R-410a 20 Year 100 Year 5000 4000 3000 2000 1000 0 R-407c R-134a R-32 R-454b R-123

- 27. 27 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 3.2 OPERATIONAL CARBON < Back to 3.1 EMBODIED CARBON Go to 3.3 AVOIDED EMISSIONS > Fuel used in emergency backup generators does not need to be estimated for ZCB-Design certiÿcation; however, it must be included in the carbon balance for ZCB-Performance certiÿcation. 3.2.1.2.1 BIOGAS The ZCB-Design Standard recognizes the beneÿts of certain forms of renewable natural gas (biogas). Eligible biogas resources that can be used onsite include gaseous products produced by the anaerobic decomposition of organic wastes from one of the following sources: 1. Sewage treatment plants; 2. Manure and other farm and food/feed-based anaerobic digestion processing facilities; or 3. Landÿll gas. Applicants must either produce their own biogas onsite, or purchase biogas from their natural gas provider for it to be eligible. Eligible biogas is treated as a zero emissions biofuel and assigned an emissions factor of zero; it does not contribute to direct emissions. ZCB-Design certiÿcation does not require a contract for the purchase of biogas; purchases are veriÿed as part of ZCB-Performance certiÿcation. However, projects must show proof that an eligible supply is available, as noted in the ZCB-Design v4 Workbook™ . 3.2.1.2.2 BIOMASS The ZCB-Design Standard does not treat all biomass as carbon neutral but does recognize the beneÿts of certain forms of renewable biomass. As such, applicants who use an onsite form of biomass may propose more speciÿc emissions factors where they can be veriÿed by a registered professional. Biomass resources used onsite that are eligible to be treated as zero emissions biofuels15 include: 1. Solid biomass removed from ÿelds and forests that are managed by following sound environmental management practices.16 Solid biomass can either be whole plants, parts of plants, or harvesting and industrial by-product residues arising from the harvesting and processing of agricultural crops or forestry products that would otherwise be landÿlled or incinerated; 2. Dedicated energy crops with a rotation of less than 10 years; and 3. Liquid fuels derived from biomass as deÿned in items (1) and (2) above, including, among other things, ethanol, biodiesel, and methanol. 15 ‘Zero emissions’ is meant to characterize certain biofuels from a net-carbon emissions perspective; it is understood that other combustion products are released during combustion. 16 Refer to UL 2854 Standard for Sustainability for Renewable Low-Impact Electricity Products for a definition of ‘sound environmental management practices’.

- 28. 28 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 3.2 OPERATIONAL CARBON Biomass resources that are ineligible to be treated as zero emissions biofuels include: 1. Municipal solid waste; and 2. Those manufacturing process by-products that have been treated in the manners listed below: i. Wood coated with paint, plastics or Formica; ii. Wood treated with preservatives containing halogens, chlorine or halide like chromated copper arsenate or arsenic; iii. Wood that has been treated with adhesives; and iv. Railroad ties. If the treated biomass types (per (2) above) comprise one percent or less by weight of the total biomass used, and the remainder is from eligible sources of biomass, all biomass may be treated as a zero emissions biofuel. Zero emissions biofuels are assigned an emissions factor of zero and do not contribute to direct emissions. ZCB-Design certiÿcation does not require a contract for the purchase of biomass; purchases are veriÿed as part of ZCB-Performance certiÿcation. However, projects must show proof that an eligible supply is available, as noted in the ZCB-Design v4 Workbook™ . 3.2.2 INDIRECT EMISSIONS Indirect emissions refer to emissions that do not occur directly within the project site, such as those emissions associated with purchased energy, water use, waste, and transportation from commuting. As detailed below, indirect emissions within the scope of ZCB-Design certiÿcation include only the emissions associated with purchased energy, such as electricity or thermal energy. 3.2.2.1 ELECTRICITY Provincial location-based electricity grid emissions factors are used to represent the average emissions of all grid-connected electricity generation in a province. Provincial location- based electricity grid emissions factors are included in the ZCB-Design v4 Workbook™ , which is periodically updated to re°ect the latest emission factors from Environment and Climate Change Canada’s National Inventory Report.17 Projects may substitute a market-based residual mix emissions factor if their local utility has published one. Residual mix emissions factors are an emerging way to account for the retirement of green power products within a speciÿc geographic boundary; however, they are not widely available in North America. Projects wishing to use this option may enter a custom emissions factor in the ZCB-Design v4 Workbook™ and provide the source of the residual mix emissions factor. 17 For the latest version of the report, go to Environment and Climate Change Canada’s National Inventory Report webpage and find the most recent Inventory Report. In past years, electricity emission factors have been in Part 3, Annex 13. Alternatively, see “C-Tables-Electricity-Canada-Provinces-Territories” on Canada’s Official Greenhouse Gas Inventory page. < Back to 3.1 EMBODIED CARBON Go to 3.3 AVOIDED EMISSIONS >

- 29. 29 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 3.2 OPERATIONAL CARBON The ZCB-Design Standard recognizes that electricity may be sourced from a district energy system or an islanded grid (a small grid not connected to the provincial grid). The emission factors for these speciÿc sources may be used where they are available and can be veriÿed by a registered professional. Projects wishing to use this option may enter a custom emissions factor in the ZCB-Design v4 Workbook™ . Electricity used by electric vehicle charging stations that service vehicles used outside the project site, regardless of whether the vehicles are °eet vehicles or otherwise, should be separately metered and excluded from the calculation of indirect emissions from grid electricity. 3.2.2.2 OWNED RENEWABLE ENERGY SYSTEMS Owned renewable energy systems, whether onsite or o˝site, reduce the need for grid electricity, fuel, heating and/or cooling, lowering the emissions associated with these energy sources. Renewable energy systems typically take the form of solar or wind power generation and solar thermal heating. If more green power is generated than energy used on an hourly basis, it contributes to the avoided emissions from exported green power (see Section 3.3.1 Exported Green Power). All environmental a˜ributes (in the form of renewable energy certiÿcates) associated with the onsite or o˝site generation and/or export of green power must be retained by the applicant and cannot be sold if the power generation is to count toward achieving a zero carbon balance. Exceptions may be made where retaining environmental a˜ributes is outside the control of the project team. Examples include where a non-negotiable net-metering contract or local energy legislation requires that the a˜ributes be surrendered to the local utility or government. 3.2.2.2.1 ONSITE Onsite renewable energy helps to improve building resilience in the face of power outages, reduces total energy use and overall demand from the electrical grid, minimizes environmental impacts from power generation facilities, and helps build the knowledge and marketplace for a distributed energy future. Applicants to the ZCB-Design program must report their total modelled onsite renewable energy. Note that the usable energy produced by the renewable energy system is the output energy from the system less any transmission and conversion losses, such as standby heat loss or losses when converting electricity from DC to AC. Onsite power generation systems may or may not be net metered. Net-metering allows a project to connect renewable power generation equipment to the local grid and receive a credit on their bill for any electricity that is exported to the grid. < Back to 3.1 EMBODIED CARBON Go to 3.3 AVOIDED EMISSIONS >

- 30. 30 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 3.2 OPERATIONAL CARBON 3.2.2.2.2 OFFSITE O˝site renewable energy systems must be new and virtually net-metered to the building seeking certiÿcation. Virtual net-metering is an arrangement with the utility whereby green power generation equipment is installed in another location and net-metered against (deducted from) the building’s electricity bill. Alternatively, o˝site systems may take the form of green power systems installed on adjacent buildings within a campus. 3.2.2.3 GREEN POWER PRODUCTS Green power products involve the purchase of bundled green power or green power environmental a˜ributes. Each kilowa˜-hour of procured green power products can replace an equivalent amount of grid electricity in the calculation of the carbon balance. Procured green power products cannot be used to reduce other sources of emissions. To qualify under the ZCB-Design Standard, green power products can be generated anywhere in Canada. However, project teams are encouraged to consider local options ÿrst. Green power products must be generated from: • Solar energy; • Wind; • Water (including low-impact hydro, wave, tidal, and in-stream sources); • Qualifying biogas (see 3.2.1.2.1 Biogas); • Qualifying biomass (see 3.2.1.2.2 Biomass); or, • Geothermal energy. Green power products purchased to meet regulatory programs may also contribute to the carbon balance provided they meet the ZCB-Design program’s requirements. For example, where a building is in a municipality or province that requires buildings to o˝set their operational energy consumption with the purchase of green power, these purchases can also be used to meet the requirements of the ZCB-Design Standard. Not all forms of green power products provide the same level of additionality. Additionality refers to the likelihood that the procurement of green power products will result in new renewable electricity generation equipment that would not otherwise have been installed. The following hierarchy has been established to ensure that project teams are aware of the di˝erent options available and can explore the highest quality options ÿrst. 1. Power Purchase Agreements (PPAs): A power purchase agreement is a contract for green power and the associated environmental a˜ributes that typically includes the purchase of a signiÿcant volume of electricity under a contract that lasts for at least ÿˆeen years. PPAs are among the highest-quality forms of green power product procurement. They are most oˆen used at the company-wide scale and are not suitable for use by a single building. PPAs are also not available in all regions of Canada. All PPAs must be certiÿed by either ECOLOGO or Green-e® Energy, or meet the requirements outlined in Appendix I – Requirements for Bundled Green Power Products that are not ECOLOGO or Green-e® Certified. All power must be from green power facilities in Canada. < Back to 3.1 EMBODIED CARBON Go to 3.3 AVOIDED EMISSIONS >

- 31. 31 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 3.2 OPERATIONAL CARBON 2. Utility Green Power: Utility green power is a product o˝ered by some Canadian utilities where the electricity and the associated environmental a˜ributes (in the form of renewable energy certiÿcates) are sold together. Unlike a PPA, utility green power purchases oˆen do not require a volume purchase or ÿxed term. All utility green power must be certiÿed by either ECOLOGO or Green-e® Energy, or meet the requirements outlined in Appendix I – Requirements for Bundled Green Power Products that are not ECOLOGO or Green-e® Certified. All power must be from green power facilities in Canada. 3. Renewable Energy Certificates (RECs): Renewable energy certiÿcates are market instruments that represent the environmental beneÿts associated with one megawa˜ hour of electricity generated from renewable resources such as solar and wind. They can be purchased from a third party. All RECs must be certiÿed by ECOLOGO or Green-e® Energy and generated from green power facilities located in Canada. ZCB-Design certiÿcation allows project teams to indicate the volume (kWh) of green power products anticipated to be purchased annually. Applicants are not required to purchase the green power products at the time of ZCB-Design submission; purchases are veriÿed as part of ZCB-Performance certiÿcation. 3.2.2.4 DISTRICT HEATING AND COOLING The ZCB-Design v4 Workbook™ requires the emissions factors for district heating and cooling systems to be entered manually.The emission factors must be veriÿed by a registered professional. 3.2.2.4.1 GREEN HEAT FROM DISTRICT ENERGY SYSTEMS Green heat is district heating that is generated using clean energy technologies or zero emissions biofuels. When the associated environmental a˜ributes are bundled in the purchase of green heat, each unit of procured green heat energy can replace an equivalent amount of district heating in the calculation of the carbon balance. Procured green heat cannot be used to reduce other sources of emissions. To claim green heat, a signed commitment le˜er from the building owner to procure green heat for the project must be provided, along with conÿrmation from the district energy provider that su˛cient green heat from non-combustion-based sources is available. The green heat must be generated from sources on the district energy system to which the building is connected. The accounting for the district energy provider’s green heat program must meet the quality criteria established by the GHG Protocol Scope 2 Guidance.18 The district energy provider must obtain an annual third-party audit of the generation and sale of green heat as well as compliance with the quality criteria. 18 World Resources Institute. 2015. GHG Protocol Scope 2 Guidance. Table 7.1 page 60. < Back to 3.1 EMBODIED CARBON Go to 3.3 AVOIDED EMISSIONS >

- 32. 32 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 3.3 AVOIDED EMISSIONS < Back to 3.2 OPERATIONAL CARBON Go to 04 LIMITS TO EMISSIONS > 3.3 AVOIDED EMISSIONS Avoided emissions are emissions reductions that occur outside of the value chain or life cycle of a building. Avoided emissions are critical to achieving a zero carbon balance. For example, they enable embodied carbon and refrigerant leaks to be mitigated. Avoided emissions must be assessed and reported in the ZCB-Design v4 Workbook™ following the direction provided below. 3.3.1 EXPORTED GREEN POWER If the renewable energy generated exceeds the energy used (as evaluated on an hourly basis) and is then exported to the electricity grid, it is recognized as contributing to avoided emissions, provided that the associated renewable energy certiÿcates are retained. Avoided emissions from exported green power can only be used to reduce indirect emissions from electricity. A project’s avoided emissions are calculated using marginal electricity grid emissions factors for each province. These factors are based on the emissions intensity of the non-baseload electricity generation, which be˜er captures the grid-level emissions reductions that are achieved (given that baseload electricity generation is una˝ected by additions of intermi˜ent renewable energy). The GHG Protocol’s Guidelines for Quantifying GHG Reductions from Grid-Connected Electricity Projects champions a marginal approach to quantify emissions reductions based on the grid-level carbon impacts. This approach is further supported by a recent working paper from the GHG Protocol titled Estimating and Reporting the Comparative Emissions Impacts of Products. This working paper advocates for avoided emissions to consider the system-level impacts when bringing products (such as buildings) to market. Project teams that would rather use provincial location-based electricity grid emissions factors to measure avoided emissions may opt to do so at their discretion. These factors are based on the average emissions intensity of all types of electricity generation within a province. In high-carbon grids where the average emissions intensity is higher than the marginal emissions intensity (for example, where baseload is substantially met with coal- ÿred electricity generation and marginal electricity is provided from other sources), using the average emissions intensity allows for more appropriate sizing of renewable energy systems and recognizes that e˝orts are underway to decarbonize Canada’s electricity grids. The ZCB-Design Standard recognizes avoided emissions from investments in carbon o˝set projects, as well as avoided emissions based on grid-level impacts from exporting green power.

- 33. 33 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 3.3 AVOIDED EMISSIONS 3.3.2 CARBON OFFSETS Carbon o°sets are a credit for reductions in greenhouse gas emissions that occur somewhere else, which can be purchased to compensate for direct emissions or indirect emissions on a per tonne basis. Carbon o˝sets are the only means of mitigating the impacts of embodied carbon and refrigerant leaks. The ZCB-Design v4 Workbook™ provides an estimate of the volume of carbon o˝sets that will be required to cover the embodied carbon of the ÿnal design and one year of operations. Applicants are required to provide a quote for the purchase of the deÿned volume of carbon o˝sets. Purchase of the carbon o˝sets is not required for ZCB-Design certiÿcation; rather, carbon o˝set purchases are required for ZCB-Performance certiÿcation, where the quantity purchased is determined based on actual building performance. High-quality carbon o˝sets ensure that o˝set projects include safeguards related to: • Additionality: The likelihood that the emissions reductions would not have happened anyway. • Permanence: The likelihood that the emissions removed will not be returned to the atmosphere later (for example, a commitment to maintain a forest could be repealed). • Leakage: The risk that emissions reductions will result in increased emissions elsewhere (for example, designating a forest as protected without precautions to prevent increased deforestation in unprotected areas). To qualify under the Zero Carbon Building – Design (ZCB-Design) Standard™, carbon o˝sets must meet one of the following criteria: • Certiÿed by Green-e® or equivalent; and/or • Derived from carbon o˝set projects certiÿed under one of the following high-quality international programs:19 • Gold Standard • Veriÿed Carbon Standard (VCS) • The Climate Action Reserve • American Carbon Registry • Sourced from Canadian provincial or federal carbon o˝set programs, including the following: • BC Carbon Registry • Alberta Emission O˝set System • Canada’s Greenhouse Gas O˝set Credit System 19 While Green-e® Climate certified carbon offsets provide the highest level of consumer confidence, additional programs are listed to ensure a diverse selection of offset project types and geographical locations are available. Applicants are only required to provide a quote for the purchase of carbon o˝sets. < Back to 3.2 OPERATIONAL CARBON Go to 04 LIMITS TO EMISSIONS >

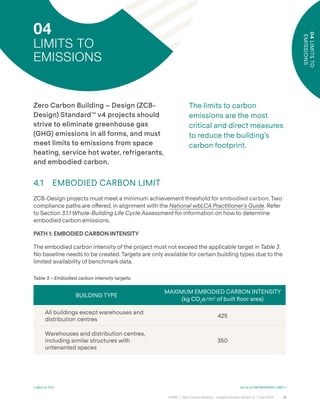

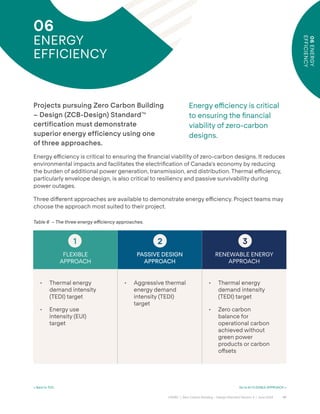

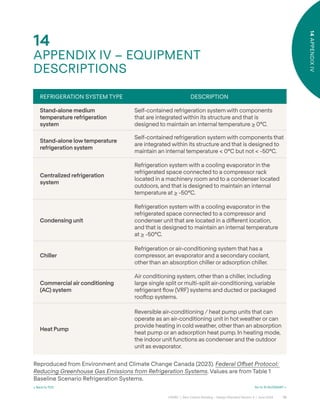

- 34. 34 CAGBC | Zero Carbon Building – Design Standard Version 4 | June 2024 3.3 AVOIDED EMISSIONS Carbon o˝sets may come from projects anywhere in the world and from any project type that meets the requirements of the programs listed above. Project teams may choose to apply their own criteria when deciding on the selection of carbon o˝sets. Carbon o˝sets purchased to meet regulatory programs may also contribute to ZCB-Design certiÿcation provided they meet the above requirements. For example, where a building is in a municipality or province that requires buildings to o˝set their carbon emissions with the purchase of carbon o˝sets, these purchases can also be used to meet the requirements of the ZCB-Design Standard. UBC Gateway, Vancouver, British Columbia, ZCB-Design v2. < Back to 3.2 OPERATIONAL CARBON Go to 04 LIMITS TO EMISSIONS >