alcoholic beverages.pdf

- 2. Fermented Alcoholic Beverage A liquor or brew containing alcohol as the active agent produced by fermentation.

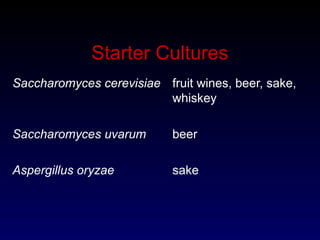

- 3. Starter Cultures Saccharomyces cerevisiae fruit wines, beer, sake, whiskey Saccharomyces uvarum beer Aspergillus oryzae sake

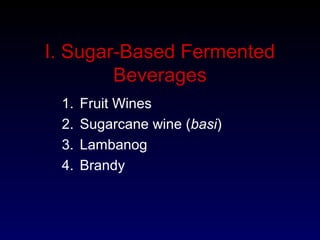

- 4. I. Sugar-Based Fermented Beverages 1. Fruit Wines 2. Sugarcane wine (basi) 3. Lambanog 4. Brandy

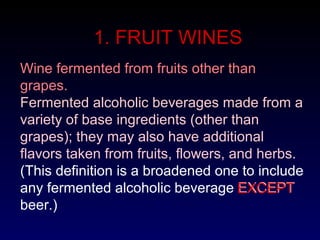

- 5. 1. FRUIT WINES Fermented alcoholic beverages made from a variety of base ingredients (other than grapes); they may also have additional flavors taken from fruits, flowers, and herbs. (This definition is a broadened one to include any fermented alcoholic beverage EXCEPT beer.) Wine fermented from fruits other than grapes. EXCEPT

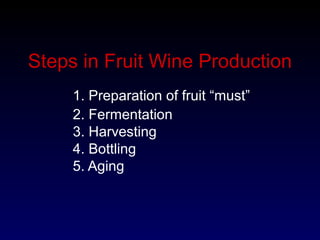

- 6. 1. Preparation of fruit “must” 2. Fermentation 3. Harvesting 4. Bottling 5. Aging Steps in Fruit Wine Production

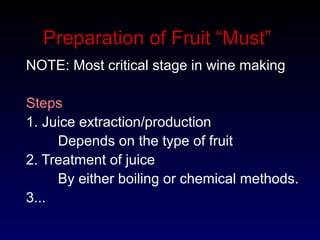

- 7. Preparation of Fruit “Must” NOTE: Most critical stage in wine making Steps 1. Juice extraction/production Depends on the type of fruit 2. Treatment of juice By either boiling or chemical methods. 3...

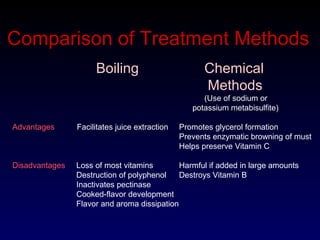

- 8. Boiling Chemical Methods (Use of sodium or potassium metabisulfite) Advantages Facilitates juice extraction Promotes glycerol formation Prevents enzymatic browning of must Helps preserve Vitamin C Disadvantages Loss of most vitamins Harmful if added in large amounts Destruction of polyphenol Destroys Vitamin B Inactivates pectinase Cooked-flavor development Flavor and aroma dissipation Comparison of Treatment Methods

- 9. Preparation of fruit “must” NOTE: Most critical stage in wine making Steps 1. Juice extraction/production Depends on the type of fruit 2. Treatment of juice By either boiling or chemical methods. 3. Adjustment of acid and sugar content

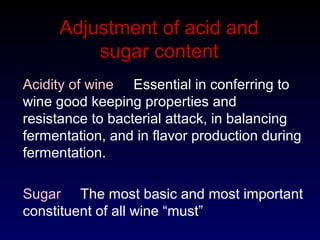

- 10. Adjustment of acid and sugar content Acidity of wine Essential in conferring to wine good keeping properties and resistance to bacterial attack, in balancing fermentation, and in flavor production during fermentation. Sugar The most basic and most important constituent of all wine “must”

- 11. 1. Preparation of fruit “must” 2. Fermentation 3. Harvesting 4. Bottling 5. Aging Steps in Fruit Wine Production

- 12. Notes In fruit wine fermentation, Pulp fermentation is useful in the production of red wine Juice fermentation is normally use in white wine processing

- 13. Factors Affecting Fermentation 1. Raw material 2. Strain of microorganism 3. Temperature 4. Oxygen requirement 5. Type of Sugar

- 14. 1. Preparation of fruit “must” 2. Fermentation 3. Harvesting 4. Bottling 5. Aging Steps in Fruit Wine Production

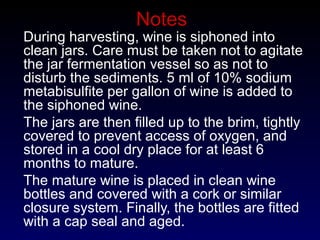

- 15. Notes During harvesting, wine is siphoned into clean jars. Care must be taken not to agitate the jar fermentation vessel so as not to disturb the sediments. 5 ml of 10% sodium metabisulfite per gallon of wine is added to the siphoned wine. The jars are then filled up to the brim, tightly covered to prevent access of oxygen, and stored in a cool dry place for at least 6 months to mature. The mature wine is placed in clean wine bottles and covered with a cork or similar closure system. Finally, the bottles are fitted with a cap seal and aged.

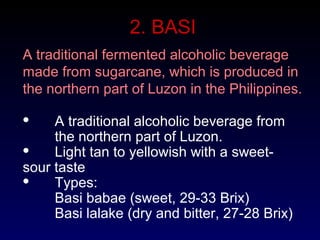

- 16. 2. BASI A traditional fermented alcoholic beverage made from sugarcane, which is produced in the northern part of Luzon in the Philippines. A traditional alcoholic beverage from the northern part of Luzon. Light tan to yellowish with a sweet- sour taste Types: Basi babae (sweet, 29-33 Brix) Basi lalake (dry and bitter, 27-28 Brix)

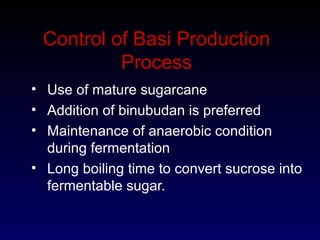

- 17. Control of Basi Production Process • Use of mature sugarcane • Addition of binubudan is preferred • Maintenance of anaerobic condition during fermentation • Long boiling time to convert sucrose into fermentable sugar.

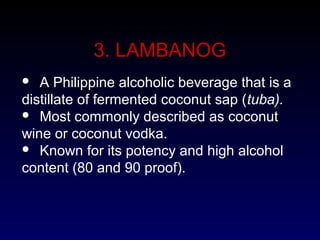

- 18. 3. LAMBANOG A Philippine alcoholic beverage that is a distillate of fermented coconut sap (tuba). Most commonly described as coconut wine or coconut vodka. Known for its potency and high alcohol content (80 and 90 proof).

- 19. Steps in Lambanog Production 1. Coconut sap collection 2. Fermentation into tuba 3. Distillation of tuba into lambanog

- 20. 4. BRANDY A spirit produced by distilling wine •A shortened form of brandywine, which comes from the Dutch word brandewijn, derived from phrase "gebrande wijn“ or "burned wine") •Generally contains 35–60% ABV (70– 120 US proof) and is •Typically taken as an after-dinner drink

- 21. II. Starch-Based Fermented Beverages 1. Rice wine (tapuy) 2. Japanese rice wine (sake) 3. Beer 4. Whiskey

- 22. TAPUY A clear full-bodied traditional alcoholic rice wine originating from Banaue and the Mountain Province with a strong alcoholic flavor, moderate sweetness and a lingering taste. •Produced from either pure glutinous rice or a combination of glutinous and non-glutinous rice together with onuad roots, ginger extract, and a powdered starter culture locally known as bubod.

- 23. TAPUY • Name derived from tapai, a fermented rice dish found in most of Southeast Asia • Alcohol content is 28 proof. • Has no sulfites (which are preservatives found in other wines) that sometimes cause adverse reactions like hang-over and allergies. • Not diluted with water and has no sugar added. • Used for important occasions such as weddings, rice harvest ceremonies, fiestas and cultural fairs. • Characteristics depend on the process and ingredients used by each manufacturer.

- 24. TAPUY 1. Weighing 2. Washing and cooking of selected rice 3. Cooling 4. Inoculation with a natural starter culture (bubod) 5. Natural pre-fermentation 6. Natural fermentation 7. Harvest 8. Pasteurization 9. Aging 10. Filtration 11. Clarification before bottling. P 12. Pasteurization 13. Sealing.

- 25. JAPANESE RICE WINE Sake, a Japanese alcoholic beverage made from fermented rice; usually served hot •Made from the following ingredients: rice, water, yeast, and a mold known as koji-kin or Koji mold. •BUT the land and craftsman expertise determine the quality of sake as well.

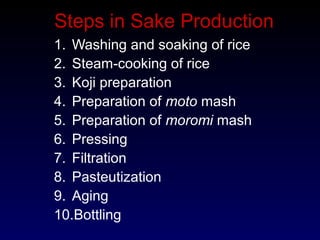

- 26. Steps in Sake Production 1. Washing and soaking of rice 2. Steam-cooking of rice 3. Koji preparation 4. Preparation of moto mash 5. Preparation of moromi mash 6. Pressing 7. Filtration 8. Pasteutization 9. Aging 10.Bottling

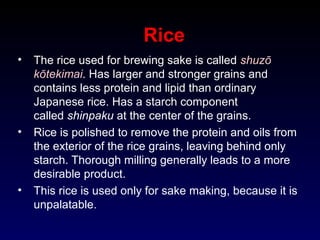

- 27. Rice • The rice used for brewing sake is called shuzō kōtekimai. Has larger and stronger grains and contains less protein and lipid than ordinary Japanese rice. Has a starch component called shinpaku at the center of the grains. • Rice is polished to remove the protein and oils from the exterior of the rice grains, leaving behind only starch. Thorough milling generally leads to a more desirable product. • This rice is used only for sake making, because it is unpalatable.

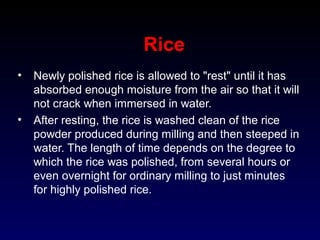

- 28. Rice • Newly polished rice is allowed to "rest" until it has absorbed enough moisture from the air so that it will not crack when immersed in water. • After resting, the rice is washed clean of the rice powder produced during milling and then steeped in water. The length of time depends on the degree to which the rice was polished, from several hours or even overnight for ordinary milling to just minutes for highly polished rice.

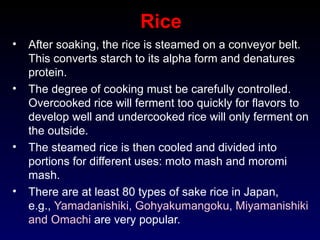

- 29. Rice • After soaking, the rice is steamed on a conveyor belt. This converts starch to its alpha form and denatures protein. • The degree of cooking must be carefully controlled. Overcooked rice will ferment too quickly for flavors to develop well and undercooked rice will only ferment on the outside. • The steamed rice is then cooled and divided into portions for different uses: moto mash and moromi mash. • There are at least 80 types of sake rice in Japan, e.g., Yamadanishiki, Gohyakumangoku, Miyamanishiki and Omachi are very popular.

- 30. Water • One of the important ingredients in sake making. • Should be colorless, tasteless and odorless • Should be neutral or weakly alkaline with only a trace amount of Fe • Mineral content plays a large role in the final product. Iron will bond with an amino acid produced by the koji to produce off flavors and a yellowish color. Manganese, when exposed to ultraviolet light, will also contribute to discoloration. Potassium, magnesium, and phosphoric acid serve as nutrients for yeast during fermentation and are considered desirable. Yeast will use those nutrients to work faster and multiply, resulting in more sugar being converted into alcohol.

- 31. Water • Hard water, with a higher nutrient content for yeast, is known for producing a drier-style sake, while soft water will typically yield sweeter sake. • The first region known for having great water is Nada- Gogō in Hyogo Prefecture. Here, a particular water source called “miyamizu" was found to produce high quality sake and attracted many producers to the region. To this day Hyogo has the most sake brewers of any prefecture. • Typically breweries source their water from wells, though lakes and rivers can be used as well. Also breweries may use tap water and filter and adjust components as they see fit.

- 32. Sake Brewing • Sake is produced by multiple parallel fermentation. • The mold Aspergillus oryzae is sprinkled onto steamed rice, which is allowed to ferment for 5–7 days. After this initial fermentation period, water and Saccharomyces cerevisiae are added to the koji (rice and mold mixture) and allowed to incubate at 4°C for about 7 days. This is called the moto mash. • Over the next four days, a pre-incubated mixture of steamed rice (90 kg), fermented rice (90 kg) and water (440 L) are added to the fermented mixture in three series. The resulting mixture is now called the main mash or moromi mash.

- 33. Sake Brewing • The moromi mash then ferments at ~15-20 °C for 2– 3 weeks. For high-grade sake, fermentation is deliberately slowed by reducing temperature to 10°C or less. • Unlike malt for beer, rice for sake does not contain the amylase necessary for converting starch to sugar; thus, it must undergo multiple fermentation. The addition of A. oryzae provides the necessary amylases, glucoamylases, and proteases to hydrolyze the rice nutrients to support the growth S. cerevisiae. • In sake production these two processes take place at the same time rather than in separate steps, i.e., via multiple parallel fermentation.

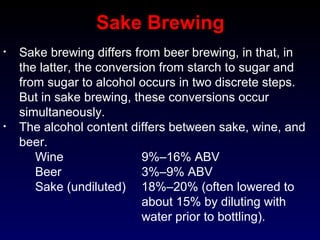

- 34. • Sake brewing differs from beer brewing, in that, in the latter, the conversion from starch to sugar and from sugar to alcohol occurs in two discrete steps. But in sake brewing, these conversions occur simultaneously. • The alcohol content differs between sake, wine, and beer. Wine 9%–16% ABV Beer 3%–9% ABV Sake (undiluted) 18%–20% (often lowered to about 15% by diluting with water prior to bottling). Sake Brewing

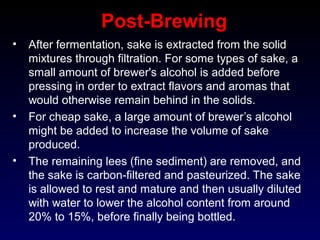

- 35. Post-Brewing • After fermentation, sake is extracted from the solid mixtures through filtration. For some types of sake, a small amount of brewer's alcohol is added before pressing in order to extract flavors and aromas that would otherwise remain behind in the solids. • For cheap sake, a large amount of brewer’s alcohol might be added to increase the volume of sake produced. • The remaining lees (fine sediment) are removed, and the sake is carbon-filtered and pasteurized. The sake is allowed to rest and mature and then usually diluted with water to lower the alcohol content from around 20% to 15%, before finally being bottled.

- 36. II. Starch-Based Fermented Beverages 1. Rice wine (tapuy) 2. Japanese rice wine (sake) 3. Beer 4. Whiskey

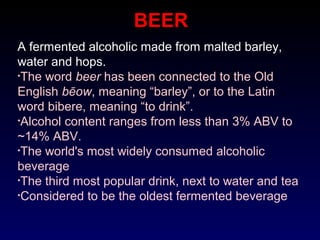

- 37. BEER A fermented alcoholic made from malted barley, water and hops. •The word beer has been connected to the Old English bēow, meaning “barley”, or to the Latin word bibere, meaning “to drink”. •Alcohol content ranges from less than 3% ABV to ~14% ABV. •The world's most widely consumed alcoholic beverage •The third most popular drink, next to water and tea •Considered to be the oldest fermented beverage

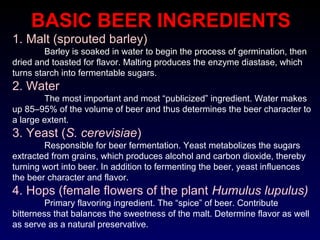

- 38. BASIC BEER INGREDIENTS 1. Malt (sprouted barley) Barley is soaked in water to begin the process of germination, then dried and toasted for flavor. Malting produces the enzyme diastase, which turns starch into fermentable sugars. 2. Water The most important and most “publicized” ingredient. Water makes up 85–95% of the volume of beer and thus determines the beer character to a large extent. 3. Yeast (S. cerevisiae) Responsible for beer fermentation. Yeast metabolizes the sugars extracted from grains, which produces alcohol and carbon dioxide, thereby turning wort into beer. In addition to fermenting the beer, yeast influences the beer character and flavor. 4. Hops (female flowers of the plant Humulus lupulus) Primary flavoring ingredient. The “spice” of beer. Contribute bitterness that balances the sweetness of the malt. Determine flavor as well as serve as a natural preservative.

- 39. BASIC BEER MAKING PROCESS 1. Mashing 2. Brewing 3. Fermentation 4. Lagering 5. Packaging

- 40. Hot water tank Malt Hops Mash tun Copper Heat exchanger Bottling Cask or Keg Fermentor Hopback Yeast addition Beer Brewing Diagram

- 41. Mashing • Grounding of malted barley with the addition of hot water • Diastase in the malt converts starch into sugar. Corn or rice is sometimes added for flavor and stability • The mash is then cooked at a low temperature for up to 6 h to extract as much sugar as possible from the grains • The resulting sweet liquid, called “wort”, is strained fro brewing

- 42. Brewing • The wort is transferred to a brew kettle, where it is boiled with hops for approximately 2 h. Such boiling also inactivates enzymes and sterilizes the mixture for subsequent fermentation. It also functions in protein coagulation, hop acid isomerization and flavor formation. • The hops are removed, and the flavored wort is strained, chilled and pumped into the fermentation tank. • At this stage, the decision to make the wort into ale or lager is made.

- 43. Fermentation • The addition of yeast to the wort to convert sugars into alcohol and carbon dioxide • Carbon dioxide is trapped in the beer by fermenting the wort under pressure • Duration: 1-2 weeks or more • At this stage, the decision to make the wort into ale or lager is made.

- 44. Lagering • The storage or conditioning of beer • In this step, the beer ripens or matures, and its flavor mellows. Duration: 1-2 weeks or more • Followed by pasteurization or filtration (eliminates leftover yeast to maintain proper flavor and alcohol level)

- 45. Packaging Many beers are packaged in bottles or cans •12 oz. bottles: case of 24 bottles, loose or six packs •12 oz cans: can of 24 or 30 cans Draft Beer •Keg (half barrel) – 15.5 gallons •Half keg (pony keg) – 7.75 gallons

- 46. Lager Fermented at 8-12°C Bottom fermentation S. carlsburgensis and S. uvarum Long brew cycle Usually brewed between 4-13°C Pale in color Lighter in taste Lower in alcohol Served cold, 4-7°C Types of Beer Ale Fermented at 18-25°C Top fermentation S. cerevisiae Quick brew cycle Usually brewed between 15-25°C Darker in color Fuller body taste Higher in alcohol Served not too cold, 10-14°C

- 47. Beer Chemistry • Beer contains the phenolic acids 4-hydroxyphenylacetic acid, vanillic acid, caffeic acid, syringic acid, p-coumaric acid, ferulic acid and sinapic acid. Most of these acids are present in bound form; only a small portion can be detected as free compounds. • Hops, and beer made with it, contain 8-prenylnaringenin, a potent phytoestrogen. They also contain myrcene, humulene, xanthohumol, isoxanthohuol, myrcenol, linalool, tannins and resin. The alcohol 2-methyl-2-butanol is a component of hops brewing. • Barley, in the form of malt, brings in the condensed tannins prodelphinidins B3, B9 and C2. • Tryptophol, tyrosol and phenylethanol are aromatic higher alcohols found in beer as secondary products of alcoholic fermentation by Saccharomyces cerevisiae.

- 48. WHISKEY A type of distilled alcoholic beverage made from fermented grain mash. •Various grains (which may be malted) are used for different varieties, including barley, corn (maize), rye, and wheat. •Whiskey is typically aged in wooden casks, generally made of charred white oak.

- 49. III. Fruit Cordial • A sparkling, clean, sweetened fruit juice from which all the pulp and other suspended materials have been completely eliminated (Vaidya et al. 2000). • A fruit juice that needs to be or need not be diluted before it is drunk. • A fruit liqeuer. Though still used in the US in this sense, it is now used to mean any fruit drink (usually a concentrate to be diluted) with an alcohol base.

- 50. Notes on Fruit Cordial Base alcohol: Either brandy or neutral distilled spirits (e.g., vodka) In cordial processing, sugar and citric acid are normally added to increase the total soluble solids and Brix value According to the Fruit Product Order Specifications, a minimum percentage of 30% total soluble solids as well as a minimum of 25% fruit juice must be reached in the final product. Often very flavorful, has a low alcohol content but a high sugar content, and is consumed after a meal. Its aroma, flavor, and taste are produced by the addition of herbs, seeds, barks, roots, plants, flowers, fruits, and peels.

- 51. Basic Methods Used in Cordial Production 1. Percolation Similar to preparing coffee. Uses a large tank as a percolator, with the spirit at the bottom and the fruit suspended on top. The spirit is pumped up and sprayed over the fruit to extract the flavor. It then drips down to the bottom. 2. Maceration Similar to brewing tea. The fruit is placed directly into the spirit and allowed to steep. 3. Distillation The fruits, leaves, or peels are placed in a still, covered with an alcoholic spirit and distilled.

- 52. Steps in Cordial Production 1. Fruit preparation 2. Sugar addition 3. Alcohol addition 4. Maceration (Steeping) 5. Straining 6. Bottling

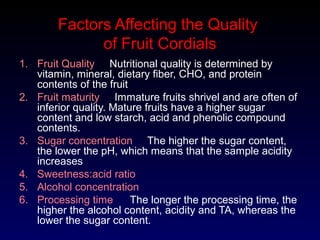

- 53. Factors Affecting the Quality of Fruit Cordials 1. Fruit Quality Nutritional quality is determined by vitamin, mineral, dietary fiber, CHO, and protein contents of the fruit 2. Fruit maturity Immature fruits shrivel and are often of inferior quality. Mature fruits have a higher sugar content and low starch, acid and phenolic compound contents. 3. Sugar concentration The higher the sugar content, the lower the pH, which means that the sample acidity increases 4. Sweetness:acid ratio 5. Alcohol concentration 6. Processing time The longer the processing time, the higher the alcohol content, acidity and TA, whereas the lower the sugar content.

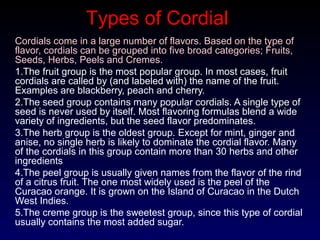

- 54. Cordials come in a large number of flavors. Based on the type of flavor, cordials can be grouped into five broad categories; Fruits, Seeds, Herbs, Peels and Cremes. 1.The fruit group is the most popular group. In most cases, fruit cordials are called by (and labeled with) the name of the fruit. Examples are blackberry, peach and cherry. 2.The seed group contains many popular cordials. A single type of seed is never used by itself. Most flavoring formulas blend a wide variety of ingredients, but the seed flavor predominates. 3.The herb group is the oldest group. Except for mint, ginger and anise, no single herb is likely to dominate the cordial flavor. Many of the cordials in this group contain more than 30 herbs and other ingredients 4.The peel group is usually given names from the flavor of the rind of a citrus fruit. The one most widely used is the peel of the Curacao orange. It is grown on the Island of Curacao in the Dutch West Indies. 5.The creme group is the sweetest group, since this type of cordial usually contains the most added sugar. Types of Cordial