powerpint presentation of radial bonding log

- 1. Radial Bond Tool Xi’an Well-sun Electronic Technology PLC 2016-08-05

- 2. 1. Well Cementing 2. Problems 3. Channeling 4. Low Compressive Strength Cement 5. RBT Logging Theory 6. RBT Structure 7. Specification 8. RBT Tool String 9. RBT Log Profile

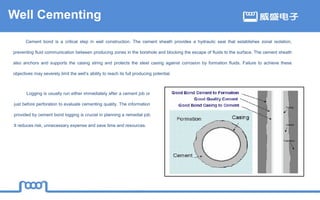

- 3. Well Cementing Logging is usually run either immediately after a cement job or just before perforation to evaluate cementing quality. The information provided by cement bond logging is crucial in planning a remedial job. It reduces risk, unnecessary expense and save time and resources. Cement bond is a critical step in well construction. The cement sheath provides a hydraulic seal that establishes zonal isolation, preventing fluid communication between producing zones in the borehole and blocking the escape of fluids to the surface. The cement sheath also anchors and supports the casing string and protects the steel casing against corrosion by formation fluids. Failure to achieve these objectives may severely limit the well’s ability to reach its full producing potential.

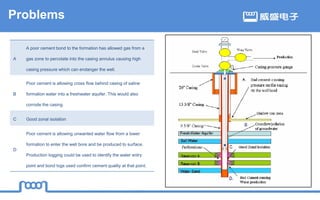

- 4. Problems A A poor cement bond to the formation has allowed gas from a gas zone to percolate into the casing annulus causing high casing pressure which can endanger the well. B Poor cement is allowing cross flow behind casing of saline formation water into a freshwater aquifer. This would also corrode the casing. C Good zonal isolation D Poor cement is allowing unwanted water flow from a lower formation to enter the well bore and be produced to surface. Production logging could be used to identify the water entry point and bond logs used confirm cement quality at that point.

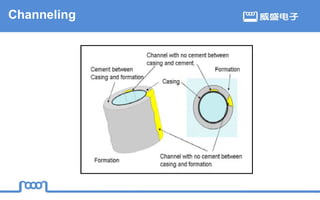

- 5. Channeling

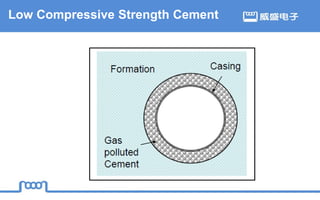

- 6. Low Compressive Strength Cement

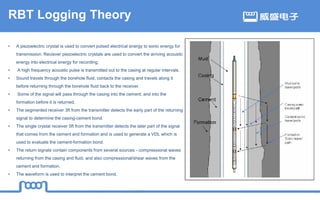

- 7. RBT Logging Theory • A piezoelectric crystal is used to convert pulsed electrical energy to sonic energy for transmission. Reciever piezoelectric crystals are used to convert the arriving acoustic energy into electrical energy for recording. • A high frequency acoustic pulse is transmitted out to the casing at regular intervals. • Sound travels through the borehole fluid, contacts the casing and travels along it before returning through the borehole fluid back to the receiver. • Some of the signal will pass through the casing into the cement, and into the formation before it is returned. • The segmented receiver 3ft from the transmitter detects the early part of the returning signal to determine the casing-cement bond. • The single crystal receiver 5ft from the transmitter detects the later part of the signal that comes from the cement and formation and is used to generate a VDL which is used to evaluate the cement-formation bond. • The return signals contain components from several sources - compressional waves returning from the casing and fluid, and also compressional/shear waves from the cement and formation. • The waveform is used to interpret the cement bond.

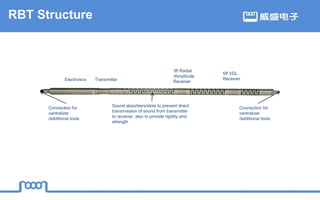

- 8. RBT Structure Electronics Transmitter 3ft Radial /Amplitude Receiver 5ft VDL Receiver Sound absorbers/slots to prevent direct transmission of sound from transmitter to receiver, also to provide rigidity and strength Connection for centralizer /additional tools Connection for centralizer /additional tools

- 9. RBT Features Realtime Logging or Memory Mode Compatible with other logging tools High Sampling Rate, Good Evaluation Performance 3D Interpretation, Intuitive Presentation H2S resistant

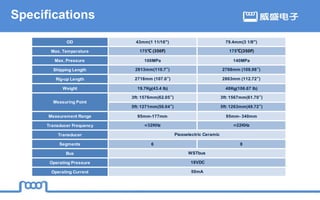

- 10. Specifications OD 43mm(1 11/16") 79.4mm(3 1/8") Max. Temperature 175℃ (350F) 175℃(350F) Max. Pressure 100MPa 140MPa Shipping Length 2813mm(110.7″) 2768mm (108.98″) Rig-up Length 2718mm (107.0″) 2863mm (112.72″) Weight 19.7Kg(43.4 lb) 48Kg(106.67 lb) 3ft: 1576mm(62.05″) 3ft: 1567mm(61.70″) 5ft: 1271mm(50.04″) 5ft: 1263mm(49.72″) Measurement Range 95mm-177mm 95mm- 340mm Transducer Frequency ≈32KHz ≈22KHz Transducer Segments 6 8 Bus Operating Pressure Operating Current Measuring Point Piezoelectric Ceramic WSTbus 18VDC 50mA

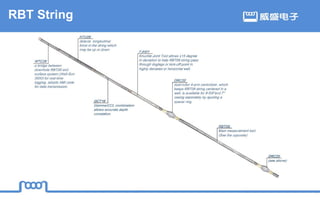

- 11. RBT String

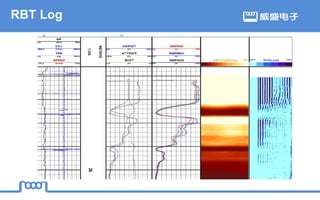

- 12. RBT Log