Design of vibratory conveyor and its applications

- 1. Supervised by: Dr. El Sayed.Saad BSc Project-2016 Vibratory Conveyors

- 2. Omar Mohamed Saad Elmahy 77 Mohamed Ahmed Elshamy 81 Mahmoud Ramadan Kamel 113 Mostafa Ashour Abdel Wahab 123 Student Name

- 3. Overview 1 Introduction To Conveyors 2 Vibratory Conveyor System 3 Theory, Design And Soft Ware Development

- 4. { }Section 1 Introduction To Conveyors

- 5. Material Handling “the art and science of moving, packaging, and sorting of substances in any form. mechanical equipment used for the movement, storage, control and protection of materials, goods and products throughout the process of manufacturing, distribution, consumption and disposal. used to create time and place utility through the handling, storage, and control of material, as distinct from manufacturing,

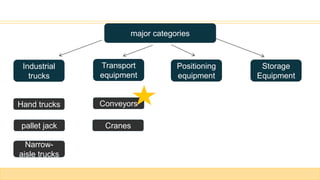

- 6. major categories Transport equipment Industrial trucks Positioning equipment Storage Equipment pallet jack Hand trucks Conveyors Cranes Narrow- aisle trucks

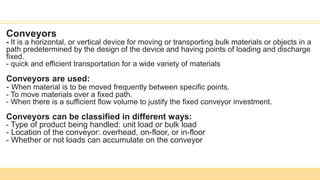

- 7. Conveyors - It is a horizontal, or vertical device for moving or transporting bulk materials or objects in a path predetermined by the design of the device and having points of loading and discharge fixed. - quick and efficient transportation for a wide variety of materials Conveyors are used: - When material is to be moved frequently between specific points. - To move materials over a fixed path. - When there is a sufficient flow volume to justify the fixed conveyor investment. Conveyors can be classified in different ways: - Type of product being handled: unit load or bulk load - Location of the conveyor: overhead, on-floor, or in-floor - Whether or not loads can accumulate on the conveyor

- 8. - Belt Conveyors - Chain Conveyors Types Of Conveyors

- 9. - Roller Conveyor - vibratory conveyors

- 10. { }1Section 2 Vibratory Conveyor Equipment

- 11. 1 Main Principle and Advantages 2 Main Application 3 Types of Vibratory conveyors

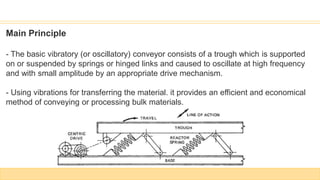

- 12. Main Principle - The basic vibratory (or oscillatory) conveyor consists of a trough which is supported on or suspended by springs or hinged links and caused to oscillate at high frequency and with small amplitude by an appropriate drive mechanism. - Using vibrations for transferring the material. it provides an efficient and economical method of conveying or processing bulk materials.

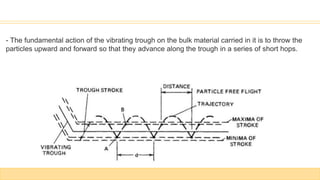

- 13. - The fundamental action of the vibrating trough on the bulk material carried in it is to throw the particles upward and forward so that they advance along the trough in a series of short hops.

- 14. Advantages - Low maintenance drive. - High material conveying capacity - Able to be used with a wide range of products - they do not require any spare parts to replace - conveying rate is much more faster than belt conveyors, thus increasing the production capacity. - Choice of Open thru or Tubular design - the material is “live” and moves independently of the conveying medium require minimum maintenance - Extremely hot materials can be handled

- 15. Main Application - Vibratory conveyors are especially amenable to adaptations which allow some kind of processing operation (such as screening, de-watering, separate, cooling or drying) to be undertaken while the product is being transported. - Feeding mineral ores or quarried stone, to a primary, secondary, or tertiary crusher - transportation of dusty, hot, toxic, and chemically aggressive bulk material - delivery of small machine parts like screws, rivets - Feeder/ conveyor for furnace charging to clinker removal. - Feeder for conveyor belt padding and crusher load control. - Feeders for packaging, blending, batching, mixing, flaking, freezing and drying operations.

- 16. Types of Vibratory conveyors 1- Horizontal Single Drive. Used to : Conveying flakes, blended materials, and coated products Scanning product. - Quick and easy to clean - It reduces material damage, coating loss, segregation, and stratification

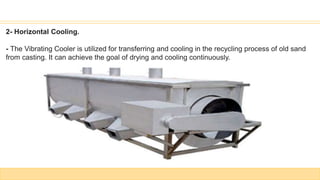

- 17. 2- Horizontal Cooling. - The Vibrating Cooler is utilized for transferring and cooling in the recycling process of old sand from casting. It can achieve the goal of drying and cooling continuously.

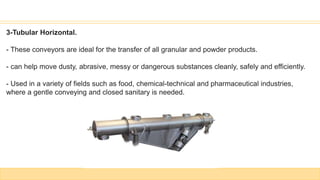

- 18. 3-Tubular Horizontal. - These conveyors are ideal for the transfer of all granular and powder products. - can help move dusty, abrasive, messy or dangerous substances cleanly, safely and efficiently. - Used in a variety of fields such as food, chemical-technical and pharmaceutical industries, where a gentle conveying and closed sanitary is needed.

- 19. 4- Spiral Vibrating Conveyor. - spiral conveyors designed as natural-frequency system that operates with a large vibration amplitude and a low vibration frequency. - Low work space with more efficiency

- 20. { }3 Theory, Design And Soft Ware Development

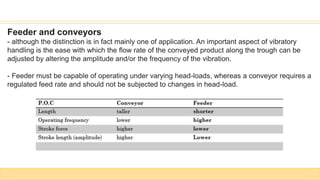

- 21. Feeder and conveyors - although the distinction is in fact mainly one of application. An important aspect of vibratory handling is the ease with which the flow rate of the conveyed product along the trough can be adjusted by altering the amplitude and/or the frequency of the vibration. - Feeder must be capable of operating under varying head-loads, whereas a conveyor requires a regulated feed rate and should not be subjected to changes in head-load.

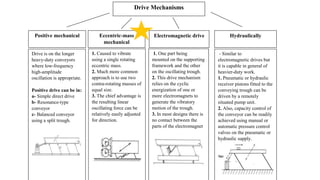

- 22. Drive Mechanisms Electromagnetic driveEccentric-mass mechanical Positive mechanical Hydraulically Drive is on the longer heavy-duty conveyors where low-frequency high-amplitude oscillation is appropriate. Positive drive can be in: a- Simple direct drive b- Resonance-type conveyor c- Balanced conveyor using a split trough. 1. Caused to vibrate using a single rotating eccentric mass. 2. Much more common approach is to use two contra-rotating masses of equal size. 3. The chief advantage is the resulting linear oscillating force can be relatively easily adjusted for direction. 1. One part being mounted on the supporting framework and the other on the oscillating trough. 2. This drive mechanism relies on the cyclic energization of one or more electromagnets to generate the vibratory motion of the trough. 3. In most designs there is no contact between the parts of the electromagnet - Similar to electromagnetic drives but it is capable in general of heavier-duty work. 1. Pneumatic or hydraulic receiver pistons fitted to the conveying trough can be driven by a remotely situated pump unit. 2. Also, capacity control of the conveyor can be readily achieved using manual or automatic pressure control valves on the pneumatic or hydraulic supply.

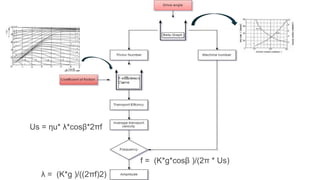

- 23. Force analysis - Throw number - Machine number - Drive angel - efficiency of transport - Material transport velocity - Solids mass flow rate

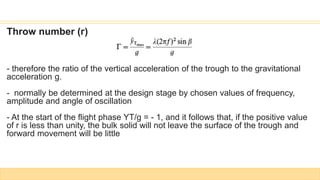

- 24. Throw number (ᴦ) - therefore the ratio of the vertical acceleration of the trough to the gravitational acceleration g. - normally be determined at the design stage by chosen values of frequency, amplitude and angle of oscillation - At the start of the flight phase YT/g = - 1, and it follows that, if the positive value of r is less than unity, the bulk solid will not leave the surface of the trough and forward movement will be little

- 25. Dynamic machine coefficient [K] - The relationship between amplitude and frequency expressed by [K] and can be represented graphically by curves. - in practice vibratory conveyors are usually designed to have K between 1 and 4.

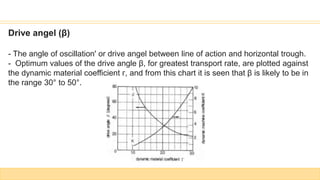

- 26. Drive angel (β) - The angle of oscillation' or drive angel between line of action and horizontal trough. - Optimum values of the drive angle β, for greatest transport rate, are plotted against the dynamic material coefficient ᴦ, and from this chart it is seen that β is likely to be in the range 30° to 50°.

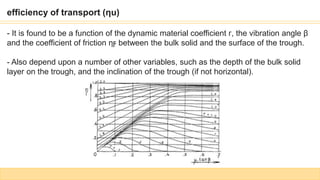

- 27. efficiency of transport (ηu) - It is found to be a function of the dynamic material coefficient ᴦ, the vibration angle β and the coefficient of friction ηϝ between the bulk solid and the surface of the trough. - Also depend upon a number of other variables, such as the depth of the bulk solid layer on the trough, and the inclination of the trough (if not horizontal).

- 28. Material transport velocity (Us) Us = ηu* λ*cosβ*2πf - Since the actual velocity of the particles in the trough will vary throughout each cycle, it is the average conveying velocity that is of significance.

- 29. Solids mass flow rate (ṁ) - can then be predicted by introducing the cross-sectional area of the bulk material in the trough and its bulk density. ṁ = ρ A Us

- 31. (ṁ) = ρm * Am * Ur U = X/t Mass = ρ * V

- 32. Us = ηu* λ*cosβ*2πf f = (K*g*cosβ )/(2π * Us) λ = (K*g )/((2πf)2)

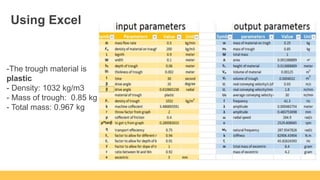

- 34. -The trough material is plastic - Density: 1032 kg/m3 - Mass of trough: 0.85 kg - Total mass: 0.967 kg Using Excel

- 36. Practical

- 38. 1-Hammer test - using impact Hammer and transducer connected to analyzer. Measuring setup

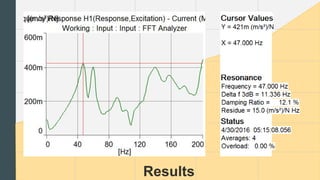

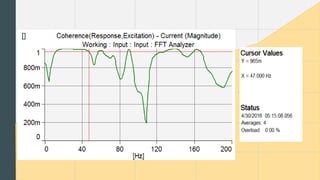

- 39. Results

- 41. 2- Velocity test - using tachometer (revolution-counter, rev-counter, RPM gauge) Measuring setup

- 43. THANK YOU

![Dynamic machine coefficient [K]

- The relationship between amplitude and frequency expressed by [K] and can be

represented graphically by curves.

- in practice vibratory conveyors are usually designed to have K between 1 and 4.](https://image.slidesharecdn.com/designofvibratoryconveyoranditsapplications-190223222917/85/Design-of-vibratory-conveyor-and-its-applications-25-320.jpg)